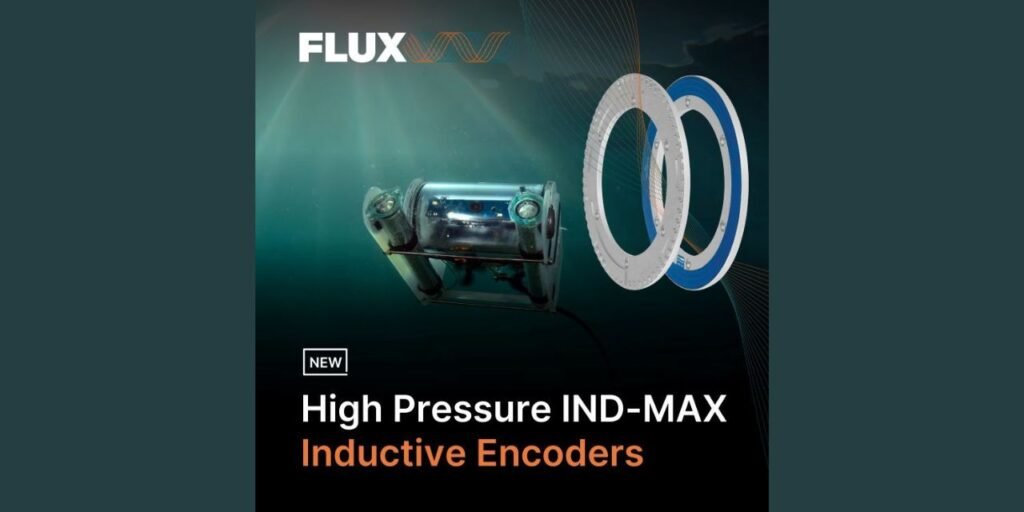

Braunau am Inn, Austria – February 13, 2025: FLUX GmbH (FLUX), a leading manufacturer of high-precision encoders, has expanded its IND-MAX range of inductive angle encoders for harsh environments by introducing a new high-pressure ‘H’ option rated up to 200 bar. This enhancement is designed to meet the demands of industries requiring high pressure resistance.

IND-MAX encoders utilize advanced inductive technology for non-contact, wear-free measurement, ensuring long-term reliability and resistance to shock, vibration, dust, oil, and moisture. The new high-pressure variant further extends the application of IND-MAX encoders to challenging environments.

Key Applications for High-Pressure IND-MAX:

- Subsea Equipment: Including underwater robotics and remotely operated vehicles (ROVs).

- Hydraulic Actuators

- Oil & Gas Exploration Equipment

- Heavy-Duty Industrial Machinery

- Marine Steering & Stabilization Systems

The IND-MAX series is available in a wide range of configurations, with standard sizes ranging from 125mm to 375mm in outer diameter. Additionally, FLUX offers customized encoder solutions to meet specific customer requirements.

Paul Tutzu, Managing Director & Founder of FLUX GmbH, stated:

“Our IND-MAX series has already set the benchmark for durability and accuracy in challenging environments. With the high-pressure variant, we are addressing the critical needs of industries where pressure resistance is essential.”

FLUX specializes in designing and manufacturing high-performance encoders for precise position and velocity feedback in closed-loop motion control systems. The company’s encoders leverage both Inductive and GMI® technologies to deliver maximum precision and reliability.