Spray Engineering Devices Ltd. (SEDL), a pioneering clean-tech engineering firm based in India, has unveiled how its patented MVR (Mechanical Vapour Recompression)-based Low Temperature Evaporation (LTE®) technology is enabling industries to move towards Zero Liquid Discharge (ZLD), while driving water recovery and operational cost savings. Delivering up to 99% clean water recovery at one-fourth the cost of conventional systems, SEDL’s technology is being adopted across diverse industries including textiles, chemicals, pharmaceuticals, distilleries, breweries, and beverages.

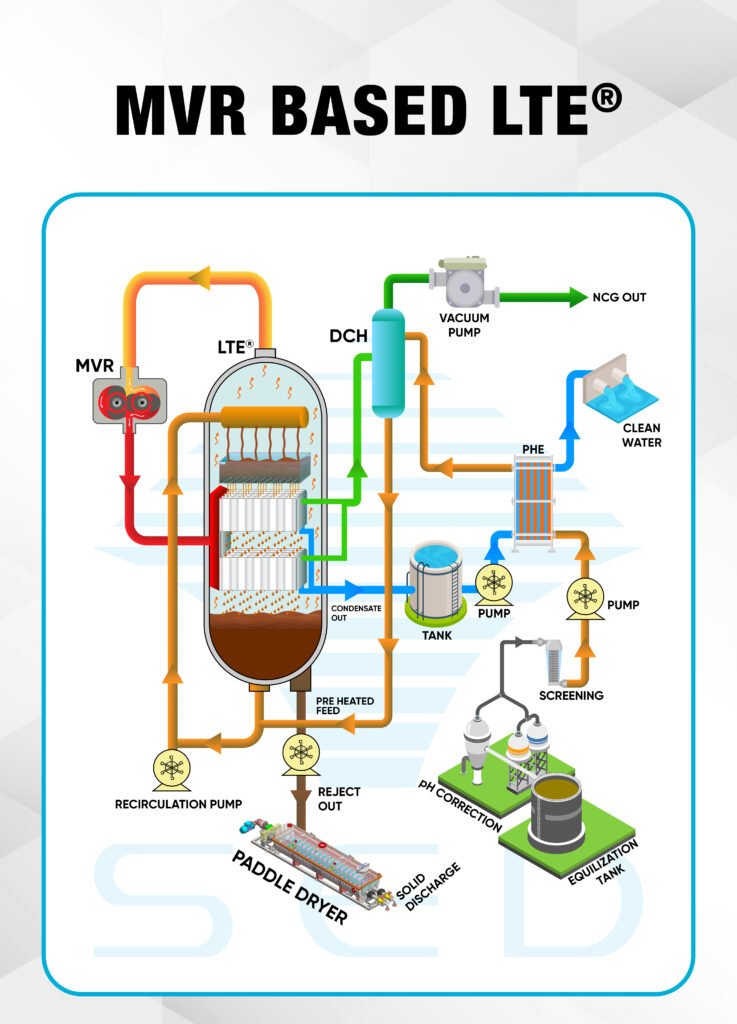

Unlike conventional steam evaporators that consume large amounts of energy, SEDL’s LTE® technology recycles heat within the process, resulting in energy use as low as 10–25 kWh/m³ and minimizing sludge generation. The dry by-product with less than 10% moisture can either be reused to create value-added products or safely disposed of in TSDF facilities.

Mr. Vimarsh Verma, Director–Operations and Head of Water & Novel Applications at SEDL, emphasized, “India’s water challenge is not just about treatment – it is about enabling industries and cities to reclaim, recycle, and reuse water at scale. Through our MVR-based LTE® systems, we are helping industries achieve water self-sufficiency while creating new revenue streams from by-products. This makes our approach both sustainable and profitable.”

The company’s solutions are already achieving measurable results across sectors. Hero Cycles (Ludhiana) recovered 91% of water with energy consumption of 20–25 kWh/m³ in electroplating. Textile players like Garg Acrylics Ltd. and Indorama India Pvt. Ltd. have achieved 97–99% recovery at reduced costs with improved water quality (TDS 50–150 ppm). In pharma and dye industries, SEDL systems are helping meet regulatory requirements, while distilleries and breweries are treating high-strength effluents and RO rejects, reducing groundwater dependence and enabling by-product valorisation.

Aligned with national priorities such as Jal Shakti Abhiyan, Make in India, and the ethanol blending program, SEDL’s systems contribute to water security, sustainability, and waste-to-wealth goals. Recognitions such as the National Energy Efficiency Innovation Award (2021) and the CII National Award for Excellence in Water Management (2019) further highlight SEDL’s leadership in merging water sustainability with industrial profitability.