In most spinning mills today, the transport of sliver cans remains a manual process. However, rising labor expenses, workforce shortages, and growing demands for quality have made this increasingly difficult. To tackle these challenges, Trützschler has launched T-CAN, an innovative, fully automated can transport system that will be demonstrated live at ITMA ASIA 2025 in Singapore.

Automation that delivers efficiency and reliability

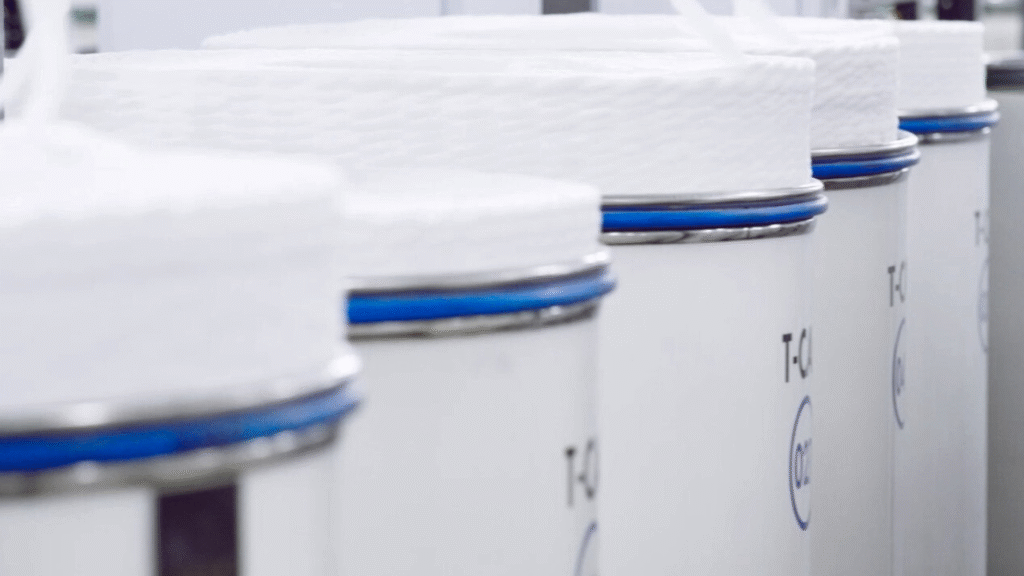

T-CAN automates the movement of sliver cans between cards, breaker draw frames, and finisher draw frames with outstanding speed and precision. It integrates automated guided vehicles (AGVs) with a smart digital control system, which monitors every step of the process to ensure that each can is positioned exactly where it belongs.

Benefits of T-CAN

The new system drastically reduces manual handling, enables continuous operation even during breaks and night shifts, and ensures material consistency through precise and automated allocation. As a result, mills can achieve lower labor costs, improved machine utilization, and enhanced sliver quality — all with a flexible system that adapts to their unique setup.

Alexander Stampfer, Chief Sales Officer at Trützschler Group, explained:

“With T-CAN, we’re responding to our customers’ needs for intelligent automation. Our goal was to create a solution that not only reduces operational costs but also enhances quality and consistency in sliver handling. It’s a leap forward in making spinning mills smarter.”

User-friendly and intuitive

Despite its advanced automation capabilities, T-CAN is remarkably easy to operate. Its intuitive software interface allows operators to manage the system with minimal training and no background in robotics.

Flexible, scalable, and ready for the future

Designed for medium to large spinning mills aiming for higher productivity, T-CAN’s modular structure makes it just as suitable for smaller mills preparing for future automation. Its scalability ensures that it grows alongside the customer’s production ambitions.

Proven success in real-world operations

The first installation of T-CAN took place at JINGYI Group, a spinning mill based in Sheyang, China. Following a successful pilot phase, the company placed an order to automate can transport for more than 120 TC 26i cards and 240 draw frames, confirming T-CAN’s reliability and strong performance.

Mr. Peng Fujian, Deputy General Manager at JINGYI Group, commented:

“We were impressed by the performance and reliability of T-CAN during the pilot phase. It has significantly improved our efficiency and reduced our staffing needs. That’s why we decided to implement it across our entire carding and draw frame section.

See it in action

Visitors attending ITMA ASIA 2025 in Singapore can experience T-CAN live at the Trützschler booth, meet with experts, and explore how this breakthrough system can enhance their spinning operations.

About Trützschler Group SE

Headquartered in Mönchengladbach, Germany, Trützschler Group SE is a global manufacturer of textile machinery operating through three business divisions — Spinning, Nonwovens, and Card Clothing.

- Trützschler Spinning leads in spinning preparation for cotton and man-made fibers, offering TRUECYCLED, a complete solution for recycling textile waste into high-quality yarns.

- Trützschler Card Clothing is the global market leader in high-performance card clothing for cards and roller cards.

- Trützschler Nonwovens provides complete production lines and machines for needle-punched, spunlaced, through-air, and chemically bonded nonwovens.

The company operates nine production sites across Germany, China, India, the USA, and Brazil, supported by service teams and subsidiaries in Türkiye, Mexico, Uzbekistan, Vietnam, Pakistan, Bangladesh, and Indonesia.

For more information, visit www.truetzschler.com.