Prasanta K. Panda

The Bombay Textile Research Association,

LBS Marg, Ghatkopar (W), Mumbai-400086

Abstract: Prefabricated vertical drains (PVD) are one kind of geotextile filter for the consolidation of soft soil before the building of a structure. This consists of a plastic core with grooves on both sides along its length, surrounded by a geotextile filter. The formed groove acts as a water channel even at large lateral pressure, whereas the surrounded geotextile filter maintains the hydraulic capacity of the grooves, preventing clogging by soil intrusion. When the pore size of the surrounding filter is larger than the fine soil particle, the internal water flow paths of PVD get clogged by fine soil particles under lateral soil pressure. Intrusion of many fines could reduce the PVD discharge capacity and increase the filter resistance. This filter jacket with an appropriate pore size can be used to prevent clogging and maintain the hydraulic capacity of the grooves. To achieve the appropriate small pore size, a thin nanofibrous membrane has been deposited on a spun bond nonwoven filter jacket membrane using a needleless electrospinning system. During electrospinning, parameters were optimized to get a uniform beadless nanofiber layer with the required diameter. Further, the thickness of the nanofiber mat was standardized to keep the pore size less than the soil particle size present in the marshy land soil. Anti-clogging property and water permeability of the membrane with a nanofiber layer were investigated after continuous use for a long time in the presence of soil. Results showed that the use of a nanofiber membrane rather than only a nonwoven membrane significantly improves anti-clogging property and maintains constant water flow. The intrusion of soil particles in the membrane pores has been observed by Scanning Electron Microscope (SEM) after use.

Keywords: Prevertical drainage, fine soils, nanofiber, anticlogging, water permeability

1. Introduction

Geotextiles are permeable textile materials that are being used with sand, soil, and rock in various areas of geotechnical structures such as roads, river and sea bank protection, canal lining, landfills, airports, railways, etc. Based on the end-use applications, they may be woven, non-woven, or knitted as per the requirement. Among the various functions of geotextiles, filtration is an important function to separate water from soil. This is because geotextiles are porous to allow the liquid flow across their manufactured plane and also within their thickness [1].

Prefabricated vertical drains (PVD) are one kind of geo-filters for the consolidation of soil before the building of a structure. This consists of a plastic core with formed grooves on both sides along its length, surrounded by a filter membrane. The formed grooves act as a channel and allow water to flow even at large lateral pressure, whereas, surrounded membrane maintains the water flow to the grooves, preventing clogging by soil intrusion [2-5].

The pressure drop across the filter media can be expressed as Dp = βηV/A, where Dp is the pressure drop, β is the resistance of the filter medium, η is the viscosity of the fluid, and V/A is the flow rate per unit area. Resistance of filter medium β = mass per unit area of the medium [6]. This relation shows that, increase in resistance of the membrane causes an increase in pressure drop. Other than the mass per unit area of the filter media, clogging of pores also causes a hike in resistance. In a certain environment, for example, marshy land soil, particles are smaller than the filter pore, under lateral soil pressure, the internal water flow paths of PVD get clogged by intrusion of those fine soil particles and increase the filter resistance [7, 8]. This phenomenon reduces the water flow and affects the consolidation process. This can be solved by making pores smaller in size to prevent clogging and larger in number to maintain the hydraulic capacity of the grooves. A smaller pore size with an increase in the number of pores per unit volume is possible by deposition of a nanofiber layer over the existing nonwoven media.

In this study, Nylon 6 nanofiber has been deposited on the surface of the spun-bonded polypropylene jacket to minimize the pore size and improve the anti-clogging property of that geotextile. The modified PVD with a nanofiber layer has been compared with conventional PVD with respect to the clogging and filtration efficiency.

2.0. Materials and Methods

Fiber grade Nylon 6 of MFI 35 was purchased from J. K. Polymers Surat (India). Spunbonded nonwoven Polypropylene fabric was supplied from Techfab (India) Industries Ltd, Daman (U.T). Acetic acid (MW 60.05 g/mol) and formic acid (MW 46.05 g/mol) were procured from Merck Life Science Pvt Ltd., Mumbai (India). All these chemicals were used as it is without any further purification.

The measured amount of acetic acid and formic acid in the required ratio was taken in a conical flask and stirred using a magnetic stirrer. Then polymer was added slowly during stirring and kept for 2h at 70˚C. The nanofiber was spun using a needleless electrospinning machine NS IS500 U from ELMARCO (Czech Republic) with a wire electrode. Electrospinning parameters such as concentration of polymer, positive electrode voltage, negative electrode voltage, distance between the electrodes, and relative humidity were standardized to get a fiber with the required diameter. Morphology of Nylon 6 nanofibers was observed by Scanning Electron Microscope (SEM) JSM 5400 from JEOL after gold coating. Quantachrome’s 3G porometer operating under windows ®, the 3G win software was used to analyze the pore size of the nanofiber layer. Water permeability in the presence of soil was measured by using a falling water head test instrument, indigenously made in our laboratory. In this falling water head tester, water was flown through the sample from a constant water head, and time was recorded after a 5cm falling of water head. In order to maintain the water head pressure constant, reading was taken after 5cm from the initial point every time.

3.0. Results and discussion

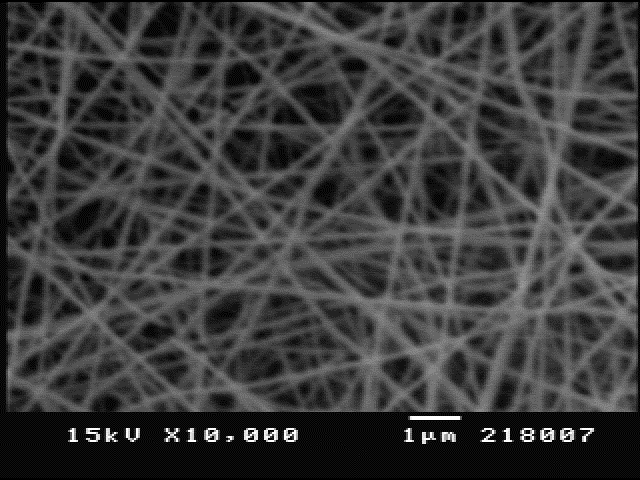

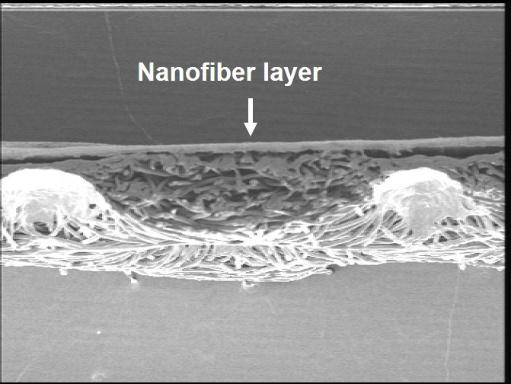

The effect of different electrospinning parameters, such as concentration of polymer, applied voltage, relative humidity %, and distance between electrodes, was standardized based on the fiber uniformity and pore size. The value of one parameter was varied within a certain range, keeping all other mentioned parameters fixed in a given set of experiments. After the experimentation, standardized values for polymer concentration, applied voltage, relative humidity %, and distance between electrodes were found to be 13wt%, 35kV, 45% and 130mm, respectively. The nanofiber spun at a standardized parameter was uniform in diameter and free form beads. The SEM image of the nanofiber at standardized parameters is given in Figure 1, and the cross-section of the PVD jacket with the nanofiber layer is given in Figure 2.

Figure 1: SEM image of Nylon 6 nanofiber at standardized parameters

Figure 2. Cross-section of the PVD filter jacket

3.1. Effect of Deposition Time on Pore Size and Water Permeability

The thickness of the nanofiber mat is inversely proportional to the water permeability, so at standardized spinning parameters, the thickness of the nanofiber mat was standardized by varying the deposition time from 0.5 min to 5 min. Significant increase in pore size and water permeability was found at 1 and 0.5 minutes of deposition. As a decrease in pore size causes an increase in filtration resistance, and an increase in pore size is not favorable to enhance the anti-clogging property of PVD, 2 min of deposition time was kept fixed for further investigation. The average pore size in the 2-minute-deposited nanofiber mat was found to be close to 0.558µm.

3.2. Water Permeability of the Nanofiber Deposited Media in the Presence of Soil

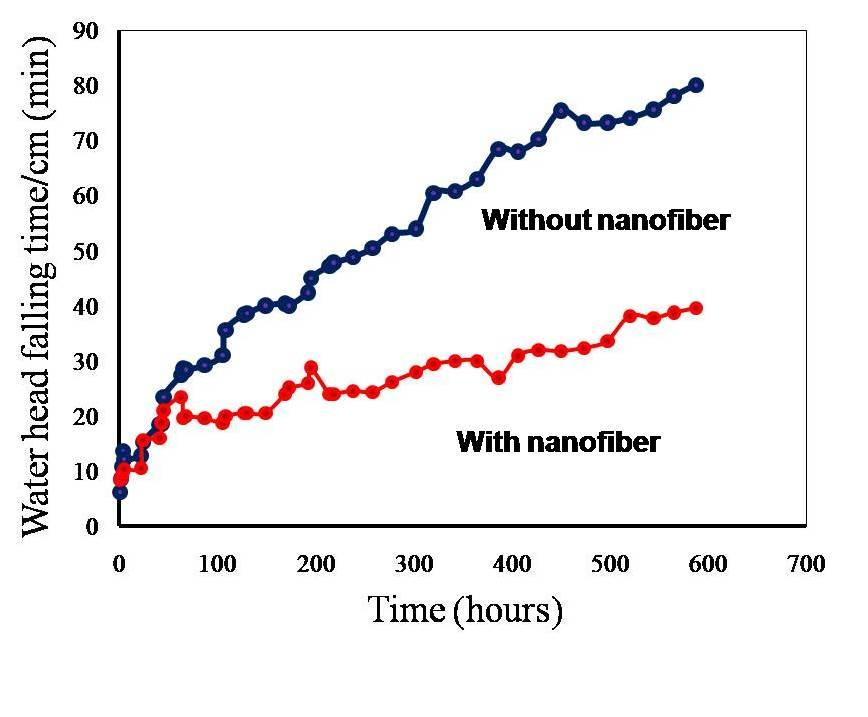

The water permeability of the existing media and nanofiber-deposited media was evaluated by a falling water head tester in the presence of soil particles. Evaluation was done by changing the soil concentration from 1 to 4% on weight of water. At 1 and 2 % soil, more water flow was observed in existing media compared to nanofiber deposited media, but the reverse of this trend was observed at 4% concentration of soil. The water flow was found to be similar for both media at 3% soil, so this concentration was taken to study the performance of nanofiber-deposited media in long-term use. In this experiment, both the media were kept continuously in the presence of soil for a long time, and the time taken for the water head to fall to 5cm was recorded continuously. The plot of water head fall time per centimeter corresponding to duration is given in Fig. 3. Initially, the time taken by water head to fall 1 cm was less in existing nonwoven media compared to nanofiber media, but after some hours, it increased and crossed the time taken through the nanofiber deposited media. This was because of the low filtration resistance of existing non-woven media, which was increasing after some hours by the intrusion of fine soil particles and clogging of pores. This phenomenon was not observed in the case of nanofiber-deposited media.

Fig. 3: Water head falling time after continuous use in the presence of soil

3.3. Analysis of Used Sample

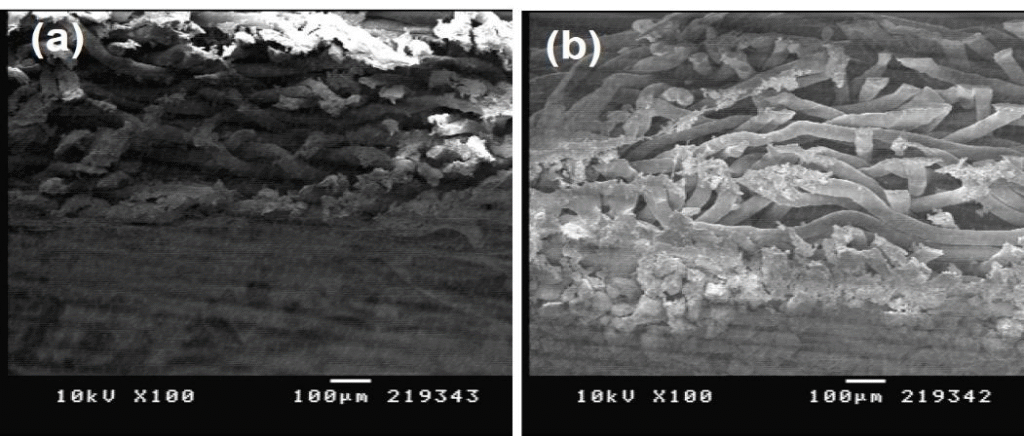

The clogging behavior of filter media after use was investigated by the scanning electron microscope (SEM). Both samples were collected from the tester after use and taken for analysis. Cross-sectional images of both samples are shown in Fig. 6 (a) and (b). Intrusion of fine soil particles into the pores was seen in conventional microfibrous media, but it was not seen in the case of nanofiber-deposited media. The pores of the microfiber media were found clean due to the presence of a nanofiber layer on it.

Fig 4. Cross-sectional view of used nonwoven media (a) without nanofiber (b) with nanofiber

4. Conclusion

The electrospinning parameters were standardized for Nylon 6 in the needleless electrospinning machine with wire electrodes. Deposition time was standardized to obtain the required pore size in the nanofiber mat. The clogging behavior and water permeability of the PVD substrate with a nanofiber mat were investigated for a long time in the presence of soil. A gradual decrease in water permeability was observed in existing nonwoven media compared to nanofiber-deposited media. This increase in time was due to the clogging of the pores of nonwoven media by the intrusion of fine soil particles. Clogging of the pores was confirmed from the scanning electron micrograph. Deposition of a thin nanofiber layer on the existing nonwoven filter media can be helpful to maintain the water flow through the channel and reduce the consolidation time before the construction.

References:

- Handbook of Geotextiles, The Bombay Textile Research Association, ISBN 978-81-7674-132-3, 3- 6, 2012.

- Vertical Drains and Smear Effects: A Brief Review, A. Dey, Geosymposium, 333-335, 2008.

- B. Indraratna, C. Rujikiatkamjorn, V. Wijeyakulasuriya, G. McIntosh,R. Kelly, Research online, http://ro.uow.edu.au/engpapers/334 , 2007.

- B. Indraratna, C. Rujikiatkamjorn, V. Wijeyakulasuriya, G. McIntosh,R. Kelly, Research online,227-246, 2010.

- S. D. Chaugule, J.N.Gulvi, M. B. Mulik, A. S. Yelve, Miss. Pritee, Mistry International Journal on Recent and Innovation Trends in Computing and Communication, 4(4), 286-287,2016.

- H.J. Choi, M. Kumita, S. Hayashi, H. Yussa, M. Kamiyama, T. Seto, C. J. Tsai, Y. Otani, Aerosol and Air Quality Research, 17, 1052-1062, 2017.

- N. Miura, Y. Park, M. R. Madhav, Journal of the Japanese Society of Civil Engineers, 483/III-25, 31-40, 1993.

- G. Mesri, D.O.K Lo, T.W. Feng, ASCE proceedings of the Prediction Symposium during the Settlement, 94ASCE Conference at Texas A&M University, College Station, Texas, USA, 1994.