Former Professor in Civil Engineering,

College of Engineering Trivandrum, Kerala.

ABSTRACT

Geotextiles made of natural fibres like coir and jute are extensively used for erosion control applications. Bureau of Indian Standard Specification on erosion control using coir geotextiles specifies three varieties of woven coir geotextiles based on their mass per unit area. However, the selection of coir geotextiles for a particular site is arbitrary and based on experience. A scientific method of selection of coir geotextiles, both woven and non-woven, based on their opening size has been discussed in this paper. The method is based on the Universal Soil Loss Equation and uses Fuzzy Logic in MATLAB. The paper also discusses the potential of coir geosynthetics in various other civil Engineering applications, which are field trialed in Kerala.

- INTRODUCTION

Soil erosion is the removal of surface layers of soil by wind, water, and ice. Soil erosion involves a process of both particle detachment and transport by these agencies. Erosion is initiated by drag, impact, or tractive forces acting on individual particles of soil at the surface. The two most common types of erosion are rainfall and wind erosion. They are controlled by a number of soil, climatic, and topographic factors, including intensity and duration of precipitation, ground roughness, length and steepness of slope, inherent soil erodibility, and type or extent of cover.

Surficial erosion by water commences when the kinetic energy of rainfall is transferred to individual soil particles, breaking the bonding between particles and moving the particles upwards and laterally. On level ground, the net transport of soil particles will be almost zero, since the soil particles splash uniformly in all directions. However, on a slope, more soil will be transported downhill by the impact. At the onset of runoff, water collects into small rivulets, which may erode every small channel called rills. These rills may eventually merge into larger and deeper channels called gullies. If the soils are permeable and have a favourable soil structure, infiltration will be enhanced and overland runoff reduced. If the energy of falling rain can be absorbed or dissipated by vegetation or impact on some other soil cover or surface obstruction, energy transfer to soil particles resulting in detachment will be reduced, consequently reducing soil erosion.

- SURFACE EROSION CONTROL TECHNIQUES

The applicability of erosion control measures varies according to the classification of the site as urban, cultivated, and pasture. Erosion control methods can be classified into three broad categories, with the applicability of the method depending on the classification of the site as Agronomic, Soil Management, and Mechanical. Ground cover is most often the solution for erosion protection. It ranges from inert facings (cement, or stone layers) to organic mulches (hay, wood chips, straw, etc.) and live materials (seeding and sod, cuttings, and transplants).

- ROLE OF VEGETATION IN EROSION CONTROL

The joint actions of trees, grass, and other plant species for the protection of soil from water/wind erosion have been recognised from time immemorial. The above-ground biomass of the grass provides adequate canopy interception to the falling raindrops, and saves the soil from splash erosion, while the mass of litter and rhizomes or stolons act as speed breakers for the running water on the slope and collect soil particles to percolate more water and store it for recharging the soil profile for better vegetation yield.

Vegetation tends to prevent surficial erosion by;

i. Binding and restraining soil particles in place

ii. Filtering soil particles out of runoff

iii. Intercepting raindrops

iv. Retarding the velocity of runoff and

v. Maintaining infiltration.

Deep-rooted woody vegetation helps to prevent shallow mass movements by

i. Mechanical reinforcement from the root system

ii. Soil water depletion through transportation and interception, and

iii. Buttressing and soil arching action from embedded stems.

- EROSION CONTROL PRODUCTS

Establishing vegetation on erosion-susceptible slopes is very difficult. Mulching has been in use for the acceleration of vegetation establishment. Benefits of mulches include;

- Assisting in soil stabilisation, which immediately reduces wind and water erosion

- Reducing soil temperatures which decreases soil moisture evaporation and heat stress upon plants

- Capturing and retaining moisture, which reduces soil moisture loss

- Capturing blowing snow, which increases the insulating effect of winter precipitation

- Decomposing into valuable organic matter that becomes incorporated into the soil

- ROLLED EROSION CONTROL PRODUCTS (RECP)

A Rolled Erosion Control Product (RECP) is a matrix consisting of various organic or inorganic materials confined by netting, stitching, and/or geo-composites. When properly placed, RECPs prevent seed and soil loss, which aids in the establishment of healthy vegetation, to prevent erosion in the future. RECPs slow down the extreme overland flow, reducing its powers of soil transportation. It helps to maintain an even temperature in the soil through its blanket effect, which can aid seed germination. Damp RECPs provide humidity, creating a micro-climate conducive to plant growth. In extreme climates, they provide considerable shading to young plants and reduce soil desiccation. These products can be classified as:

- Erosion Control Nettings (ECN)

- Erosion Control Meshes (ECM)

- Erosion Control Blankets (ECB) with single/double knot

- Geosynthetic (Polymeric) Mattings or Turf Reinforcement Mats (TRM)

- Geocells (Cellular confinement systems)

- Gabion Baskets and Mattresses

- SELECTION OF RECB

Based on the soil type, slope angle, and length, intensity or rainfall, vegetation crop factor, and erosion control practice factor, an appropriate RECB can be selected. Based on the Universal Soil Loss Equation, a MATLAB-based technique has been developed by which the most economical and effective RECB can be selected. For erosion control, the Annual Soil Loss should be less than or equal to 5 t/ha/year. The geotextile type has been selected for each variety of soil and slope, which brings down the Annual Soil Loss quantity to equal or less than 5 t/ha/year. When high opening sizes than mentioned in the tables are used for a particular combination of soil type, slope angle, rainfall intensity, etc, then the percentage erosion control will be less than 100% as seen from the charts.

From the models, depending on the rainfall intensity, the type of coir geosynthetic that can be selected for various slopes and soil types is given in Tables 1 to 3. Tables 1 to 3 can be used as a guideline for selecting the appropriate variety of coir geotextiles (having specified opening size) for erosion control applications. Since the basis of the selection is purely based on opening size, these guidelines can be extended for other natural fibre geosynthetics also.

Properties of woven coir mesh mats are given below.

| Sl. No. | Description of properties | Value for different mesh mats | ||

| 400 gsm | 700 gsm | 900 gsm | ||

| 1 | Mass per unit area (IS 15868); gsm | ≥ 400 | ≥ 700 | ≥ 900 |

| 2 | Tensile strength (IS 13162 (5)); kN/m (M/D) | ≥ 7 | ≥ 8 | ≥ 15 |

| 3 | Tensile strength (IS 13162 (5)); kN/m (XM/D) | ≥ 4 | ≥ 8 | ≥ 8 |

| 4 | Extension % at Max. load | > 20 | > 20 | > 20 |

| 5 | Opening size, mm (IS 15868) | 15.6 x 20.5 | 7.50 x 7.30 | 4.2 x 5.1 |

Table 1: Types of geotextiles woven/non-woven for varying rainfall intensity for 20% Slope

| Soil Type/ Rainfall | VL | ML | L | VM | M | MH | H | VH | SH |

| S | — | — | — | MO | MO | LO | LO | LO | L4 |

| C | HO | MO | L4 | L3 | L2 | L2 | L1 | L1 | L1< |

| FS | — | HO | MO | LO | L4 | L4 | L4 | L4 | L3 |

| SCL | HO | MO | LO | L3 | L3 | L2 | L1 | L1< | L1< |

| SL | — | MO | LO | L4 | L3 | L3 | L2 | L2 | L1 |

| LS | — | — | HO | MO | LO | LO | L4 | L4 | L3 |

| SC | HO | MO | LO | L3 | L3 | L2 | L1 | L1< | L1< |

| SiC | HO | LO | L4 | L3 | L2 | L2 | L1 | L1 | L1< |

| L | MO | LO | L4 | L3 | L2 | L1 | L1 | L1< | L1< |

| SiCL | MO | LO | L4 | L2 | L2 | L1 | L1 | L1< | L1< |

| SiL | MO | LO | L3 | L2 | L1 | L1 | L1< | L1< | L1< |

| Si | MO | LO | L3 | L2 | L1 | L1 | L1< | L1< | L1< |

| G | — | — | — | — | — | — | HO | HO | LO |

Note: Opening size: Woven Geotextiles: HO = 25.4 mm; MO = 12.7 mm; LO = 6.35 mm;

Non woven Geotexiles L4 = 3 mm; L3 = 1.5 mm; L2 = 1 mm; L1 = 0.3 mm

Rainfall Intenisty: VL = Very Low; ML = Moderately Low; L = Low; VM = Very Moderate; M = Moderate; MH = Moderately High; H = High; VH = Very High; SH = Severly High

Soil Types: S = Sand; C = Clay; FS = Fine Sand; SCL = Sandy Clay Loam; SL = Sandy Loam; LS = Loamy Sand; SC = Sandy Clay; SiC = Silty Clay; L = Loam; SiCL = Silty Clay Loam; SiL = Silty Loam; Si = Silt; G = Gravel.

Table 2: Types of geotextiles woven/non-woven for varying rainfall intensity for a 30% Slope

| SOIL TYPE | VL | ML | L | VM | M | MH | H | VH | SH |

| S | MO | LO | L4 | L3 | L2 | L2 | L1 | L1 | L1< |

| C | L3 | L2 | L1 | L1< | |||||

| FS | LO | L4 | L2 | L1 | L1< | ||||

| SCL | L4 | L2 | L1 | L1< | |||||

| SL | L4 | L3 | L1 | L1< | |||||

| LS | MO | LO | L3 | L2 | L1 | L1 | L1< | ||

| SC | L4 | L2 | L1 | L1< | |||||

| SiC | L3 | L1 | L1< | ||||||

| L | L3 | L1 | L1< | ||||||

| SiCL | L3 | L1 | L1< | ||||||

| SiL | L2 | L1 | L1< | ||||||

| Si | L2 | L1 | L1< | ||||||

| G | — | — | MO | LO | LO | LO | L4 | L3 | L3 |

Table 3: Types of geotextiles woven/non-woven for varying rainfall intensity for 40% Slope

| SOIL TYPE | VL | ML | L | VM | M | MH | H | VH | SH |

| S | MO | LO | L3 | L2 | L1 | L1 | L1< | ||

| C | L3 | L1 | L1< | ||||||

| FS | LO | L3 | L2 | L1< | |||||

| SCL | L3 | L1 | L1< | ||||||

| SL | L3 | L2 | L1 | L1< | |||||

| LS | LO | L4 | L3 | L1 | L1< | ||||

| SC | L3 | L1 | L1< | ||||||

| SiC | L2 | L1 | L1< | ||||||

| L | L2 | L1< | |||||||

| SiCL | L2 | L1< | |||||||

| SiL | L1 | L1< | |||||||

| Si | L1 | L1< | |||||||

| G | — | HO | MO | LO | L4 | L4 | L3 | L3 | L2 |

Properties of the stitched coir blanket with PP net on top and bottom are given below;

| Description | Details |

| Fibre type | 100% Coir |

| Width x Length | 2.40 m x 42 m |

| Unit weight | 450 gsm |

| Top & Bottom Netting | 14 x 14 mm; 4.8 gsm |

| Stitching thread | HDPE Monofilament (brown), UV stabilised |

| Tensile strength as per ISO-10319 | 0.14 kN/m |

| Maximum permissible shear stress | 1.1 g/sq.m |

- COIR GEOSYNTHETICS AS SEPARATOR (BASAL REINFORCEMENT IN FILLING OR IN PAVEMENTS)

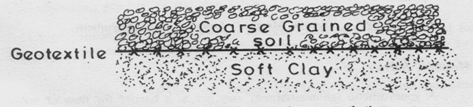

When earth filling is required over soft soil, the filled soil may penetrate into the soft soil. This merging of filled soil with existing soft soil can be prevented by using closely woven coir geosynthetics or stitched coir blankets as a separator. Geotextiles have to be laid over the soft soil before dumping the soil. Mesh mattings of 900 g/m2 or closely woven single strand panama weave mats having a mass per unit area greater than 900 g/m2 can be used. In the case of stitched coir blankets, geotextiles having a unit weight of more than or equal to 500 g/m2 are effective.

The soft soil gets consolidated under the weight of the filled up soil and gains its strength. Initially, coir geosynthetics improve the bearing capacity of clayey soil. Since coir geosynthetics is under the filled-up soil, the strength reduction of coir with time is very slow and will be in intact condition for 5 to 10 years. By this time, the soft soil will gain sufficient strength to carry the filled-up soil safely.

- COIR GEOSYNTHETICS AS A FILTER MATERIAL ON THE BACKSIDE OF RETAINING WALLS

A non-woven or stitched coir blanket of 450 g/m2 can be used as a filter material in the backfill side of a retaining wall. Coir geosynthetics will retain the fine soil particles from eroding away. Closely woven single strand panama weave coir geosynthetics of about 1000 g/m2 is also ideal for this application.

- COIR AS A FILLER MATERIAL IN GABION WALL CONSTRUCTION

A non-woven or stitched coir blanket of 450 g/m2 can be used as a filler material in the gabion netting. This will facilitate vegetation growth on the face of gabion blocks. An established method of solution for greenery and sustainable infrastructure projects all over the world.

- COIR AS A HORIZONTAL REINFORCEMENT MATERIAL IN CLAY BUNDS

Coir geosynthetics of 400 gsm, 700 gsm, and 900 gsm can be used as a reinforcement material in the clay bunds constructed in Kuttanad and also in Kole Paddy fields in Thrissur and Malappuram districts of Kerala. Horizontal reinforcement of the clay bund will reduce the earth pressure acting on the retaining wall, and thereby, the life of the retaining wall can be increased. PWD Irrigation Department has used this method for the reconstruction of breached bunds in the D block of Kuttanad in Kerala.

- COIR IN ROAD CONSTRUCTION

- To Increase the CBR of Subgrade

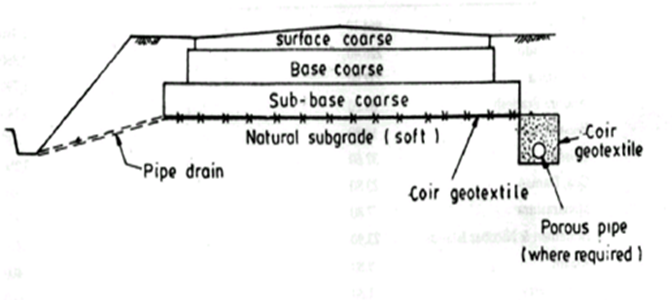

Woven mesh mats as well as non-woven, stitched coir blankets are used for this purpose, especially when the CBR value of subgrade soil is less than or equal to 4. Reported Laboratory studies by various agencies have shown that non-woven geotextile is superior to woven in such applications. Woven geotextiles of 700 to 1000 g/m2 or non-woven stitched coir blanket of 500 g/m2 are ideal for such applications. Geotextiles will be laid over the subgrade level, before the subbase level.

The thickness of pavement layers can be reduced with the use of geotextiles; however, it is recommended to maintain the same thickness and give a geotextile reinforcement additionally to improve the CBR values.

Since the sub base, base, and surface coating are there above the geotextiles, or in other words, as the geotextile is buried under soil, it will not decay as fast as if it were open to air. A lot of field trials have been conducted by the College of Engineering Trivandrum, National Institute of Technology at Calicut, and Trichi under the Coir Board-funded projects in this regard, and obtained satisfactory results and established the laboratory findings.

- Coir as a Capillary Break

Capillary rise of water from subgrade to paving surface through base course and subbase course, as in Kuttanad region or waterlogged areas, can be prevented by coir geotextiles. Aggregate sand witched between two non-woven coir geosynthetics (stitched coir blanket) of more than 500 gsm with PP net on top and bottom, or closely woven coir geosynthetics of 900 to 1100 g/m2 at the bottom and stitched blanket on top is ideal for this purpose. An aggregate fill of 20 cm to 30 cm thick will be sufficient for the capillary break drainage system. This system has been field trialed in Thanneermukkam – Vaikkom Road in Alleppey, Kerala, through PWD.

- Edge Drains (French Drains) of Pavements

Road edge drains can be constructed with closely woven coir geosynthetics or with stitched coir blankets. Woven geosynthetics of 900 g/m2 to 1200 g/m2 single strand panama weave can be used in this case. Stitched coir blankets with PP net on top and bottom, having a unit weight of 500 gsm, can be used. The aggregate used can be of any size, depending on the discharge capacity required. Graded aggregate is not necessary.

With the passage of time, a soil filter cake will be formed in the natural soil. Thereafter, the function of the coir geotextile as a filter is not needed. This will take hardly 2 to 3 seasons of rainfall.

REFERENCES

- Anupriya S.G., Sheela Evangeline, Sayida, M.K., Sumy Sebastian and Das Anita Ravindranath, (2017).” Study on the Performance of Coir Geotextile Reinforced Flexible Pavements”, Compendium of Research Articles, National Coir Research & Management Institute, Thiruvananthapuram.

- Balan, K. (1995). Studies on Engineering Behaviour and Uses of Geotextiles with Natural Fibres, Ph.D Thesis Submitted to Indian Institute of Technology, Delhi.

- Balan, K., (2017). “Coir Geotextiles in Road Construction”, Compendium of Research Articles, National Coir Research & Management Institute, Thiruvananthapuram.

- Balan, K., Sheela Evangeline, Y., and Venkatappa Rao, G., (Editors), (2016). “Coir Geotextiles (Coir Bhoovastra) for Sustainable Infrastructure”, Publication No. 331, Central Board or Irrigation and Power, and Indian Chapter of International Geosynthetics Society, New Delhi.

- Balan, K. and Praseeja, A.V., (2015). “Numerical Modeling for the Selection of Coir Geotextile for Erosion Control Application based on Universal Soil Loss Equation (USLE), Journal of Computing in Civil Engineering, American Society for Civil Engineering, Vol. 29, No.6 ISSN 0887-3801/04014102(11).

- Coir Geotextile – A Sustainable Reinforcing Material for Pavement Construction, Department of Civil Engineering, NIT, Tiruchirappalli, Tamilnadu, IICF 2016, Coir Board, Cochin.

- Venkatappa Rao, G and Balan, K., (Editors), (1994). “Coir Geotextiles – Emerging Trends” The Kerala State Coir Corporation, Alappuzha.

- Guideline No. GE: G-4, (2005). Guidelines on Erosion Control and Drainage of Railway Formation, Ministry of Railways, Govt. of India.

- IS: 15872, 2009: Guidelines for application of coir geotextiles (coir woven Bhoovastra) for rainwater erosion control in roads, railway embankments and hill slopes.