Researchers at ETH Zurich have developed innovative smart textiles that use acoustic waves and glass fibres to conduct precise measurements. These textiles are lightweight, breathable, and cost-effective, offering immense potential across medical, sports, and everyday applications.

Key Highlights:

- Smart textiles use acoustic waves instead of electronics to detect touch, pressure, and movement.

- Known as SonoTextiles, the system employs glass microfibres that carry sound signals, with minimal computational demand due to varying frequencies.

- Potential uses span from health monitoring in asthma patients to enhancing sports training and enabling gesture-based interfaces like sign language translation.

Imagine a T-shirt that tracks your breathing or gloves that translate hand gestures into computer commands. This vision is becoming a reality thanks to research led by Daniel Ahmed, Professor of Acoustic Robotics for Life Sciences and Healthcare at ETH Zurich. Unlike traditional smart textiles based on electronic sensors, this system uses acoustic waves through glass fibres, enabling more accurate measurements while keeping the fabric light, breathable, washable, and inexpensive. “They are also inexpensive because we use readily available materials, and the power consumption is very low,” says Ahmed.

Acoustic Fibres as Smart Sensors

The ETH team calls this development SonoTextiles. The fabric, embedded with glass fibres at fixed intervals, functions as a responsive sensor to touch and movement. “While research has already been conducted into smart textiles based on acoustics, we are the first to explore the use of glass fibre in combination with signals that use different frequencies,” explains Yingqiang Wang, the study’s first author published in Nature Electronics.

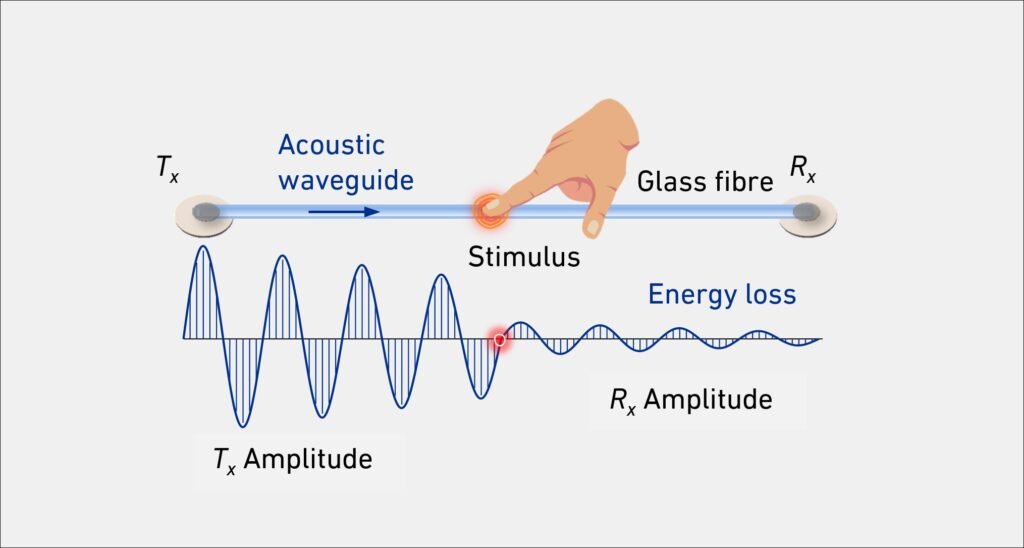

Each glass fibre has a transmitter on one end emitting sound waves and a receiver on the other detecting changes. Because each transmitter operates on a unique frequency, identifying the fibre with altered wave patterns requires minimal computational effort. This simplifies signal processing and reduces the common issue of data overload in earlier smart textile systems. “In the future, the data could be sent directly to a computer or smartphone in real time,” adds Ahmed.

As a glass fibre flexes, the acoustic wave inside changes length and loses energy, allowing motion detection—even breathing—on a garment like a T-shirt. “We used frequencies in the ultrasonic range, around 100 kilohertz – well beyond the range of human hearing, which is between 20 hertz and 20 kilohertz,” Wang notes.

Applications with Broad Potential

Lab results have confirmed that the SonoTextile concept works. Possible applications include wearable monitoring for asthma patients that can sound alarms when necessary, and athlete performance tracking with real-time feedback to enhance movement efficiency and injury prevention.

The technology also shows promise in sign language translation, where gloves could convert gestures into text or speech, and in virtual or augmented reality systems. “SonoTextiles could even measure a person’s posture and improve their quality of life as an assistive technology,” says Chaochao Sun, co-first author of the study. These textiles could notify wheelchair users when it’s time to shift positions, helping prevent pressure sores, or assist users in correcting poor posture.

While SonoTextiles show vast practical potential, Ahmed acknowledges that improvements are needed for real-world use. Glass fibres, although effective in the lab, might not withstand daily wear and tear. “The beauty is that we can easily replace the glass fibres with metal. Sound also propagates effectively through metal,” Ahmed explains, adding, “We would like to expand our research in this direction and also into other applications.” The team aims to improve system robustness and better integrate electronics into the fabric.