Ground Improvement Application

Project description:

Industrial-scale tanks are large and heavily loaded structures. These tanks are constructed with relatively thin walls that are used for storing fluids. Unforeseen ground deformations can have an undesired impact on the tank and ultimately affecting tank performance and may result in tank failure. Therefore, stakeholders decided to use TechDrain PVD to prevent ground deformations at a later stage.

Project Challenges:

Oil storage tanks were located in an area where the soils are weak and compressible. Bearing capacity under heavy loads is always a challenge, and if shallow foundations result in settlement and damage over time, it can be costly. It was necessary to do ground improvement to increase soil bearing capacity and control settlement, deep foundations to transfer loads to competent bearing strata, or drainage to accelerate consolidation of saturated soils before construction.

With consideration that tanks are relatively thin structures, unforeseen and unaccounted ground deformations can impede the performance of the tanks and ultimately lead to tank failure. Hence, the implementation of specific foundation techniques has become common practice when in-situ ground conditions are not able to provide foundations with the required bearing or deformation limitations.

Solution:

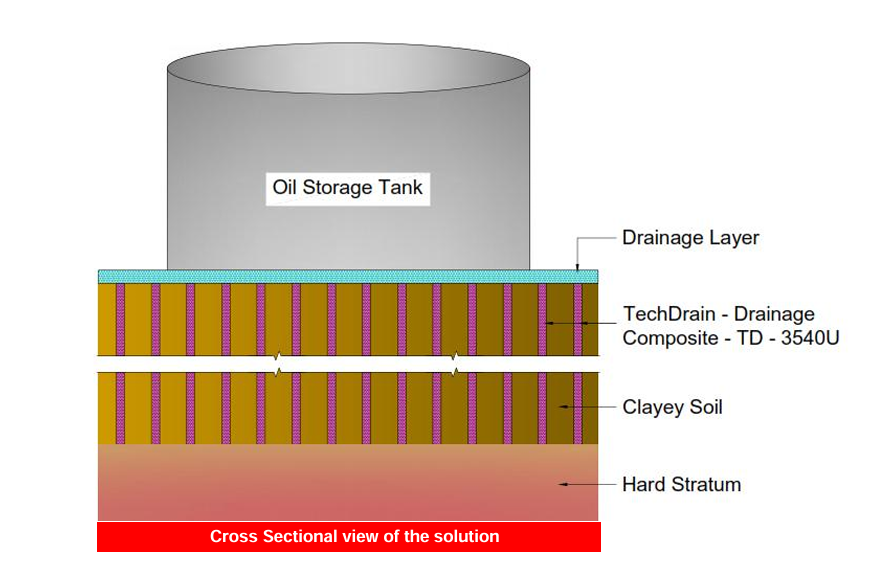

Conventionally, Ground improvement was done by using stone columns for shallow depths and by using sand drains, but for deep clayey soil, it becomes costly and time-consuming, and not very effective functionally.

A tailored solution was needed to mitigate excessive deformations and avoid future problems. Nowadays, it is common practice to use TechDrain PVD instead of sand drains for deep soil ground improvement.

Ground improvement techniques are soil replacement, preloading, sand drain, stone columns, and prefabricated vertical drains. Many projects have been undertaken by implementing one or more ground improvement techniques for effective and fast results. In this project, PVDs installation and preloading are adopted for faster mitigation liquefaction of soil.

Why does PVD perform better than sand drain?

- Easy and Faster installation

- Cause less soil disturbance during Installation.

- Can withstand lateral displacement or bucking under horizontal or vertical soil movement

- Decrease primary consolidation time from years to months

PVDs are installed through soft clayey soils to accelerate the speed of consolidation of foundation soil by reducing drainage paths. They are only effective when used in conjunction with preloading.

PVDs are the most suitable and cost-efficient ground engineering technology. This method accelerates the consolidation of the soil beneath the tanks, stops any liquid from penetrating into the sensitive soil, and prevents any future damage.

Execution on Site:

TechDrain PVD was installed by using static methods.

- PVD is enclosed in a tubular steel mandrel of small cross-sectional area, usually 50X125mm. A small steel anchor plate is attached to the drain at the bottom of the mandrel.

- The mandrel is then driven into the soil either with a static or vibratory rig. When the design depth is reached, the mandrel is extracted.

- The anchor plate retains the drain in the soil.

- When the mandrel is fully extracted, the drain is cut off. A New anchor plate is installed, and the process begins again.

- Typically, between 5000 to 20,000 m of PVD can be installed in a day, depending upon equipment, ground, and working conditions.

- We can arrange the installation of PVDs at the client’s site through our associates.

Conclusion:

The client was really happy with the prompt supply of the Best quality materials by TechFab India industries Ltd., India. TechFab India has supplied 13,80,000 LM of TechDrain PVD TD-3540U in two months.