KIPAS Textiles, one of Europe’s largest integrated textile manufacturers, has announced the launch of fibR-e, a new recycling platform aimed at addressing long-standing barriers preventing polyester from becoming fully circular.

Polyester dominates global apparel production, yet less than 1% of polyester-based garments are recycled back into new clothing. Most post-consumer material continues to be landfilled or incinerated. With new regulations pushing brands to take responsibility for product lifecycles, demand for scalable recycling solutions has increased.

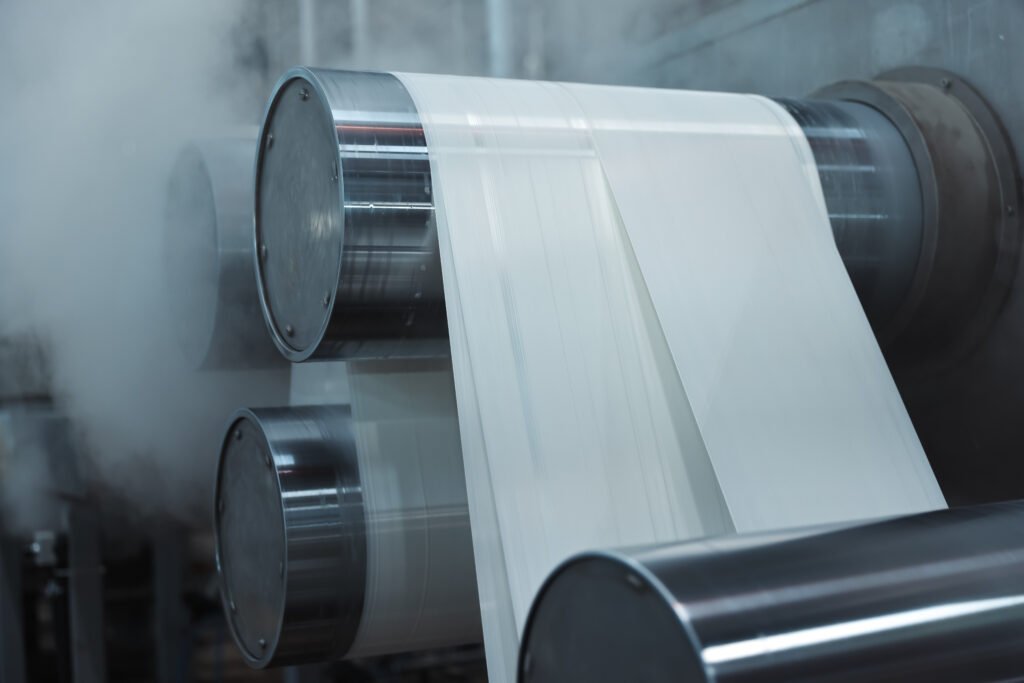

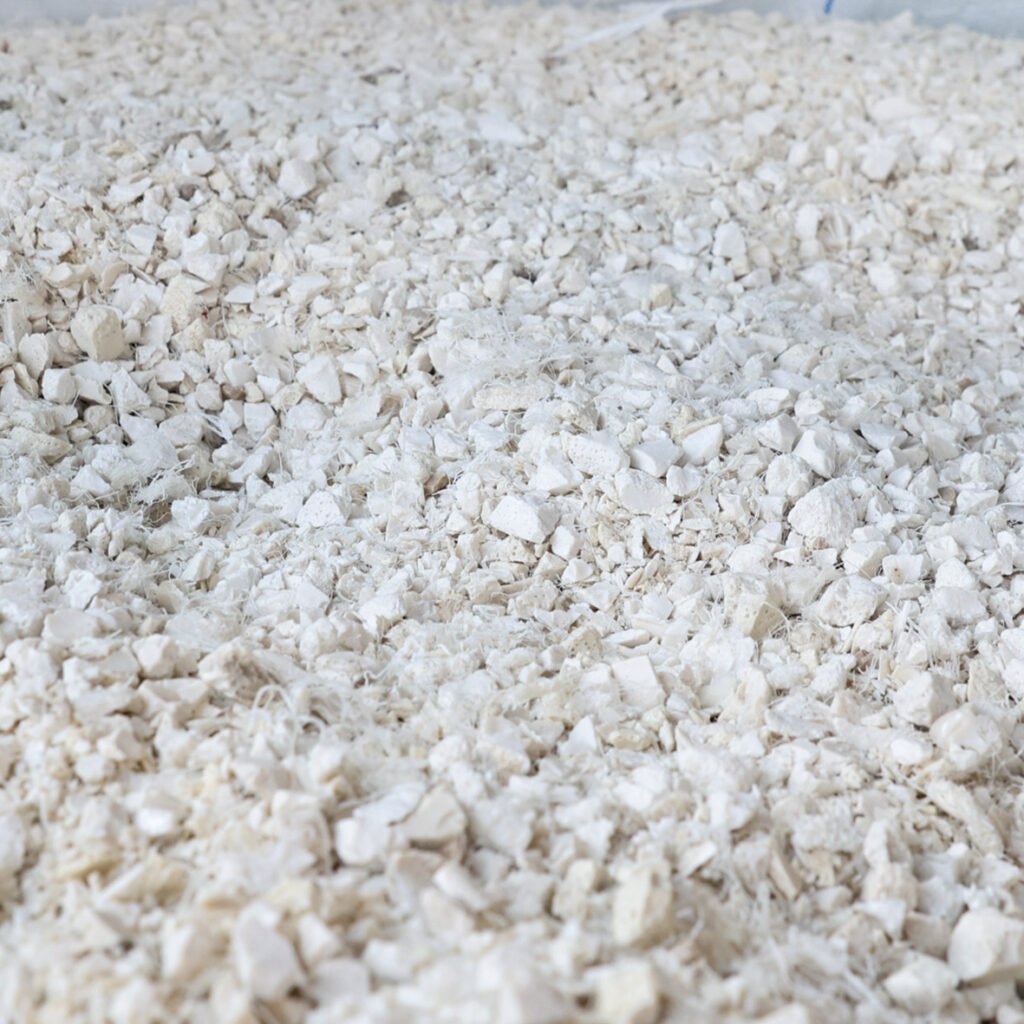

The fibR-e platform processes post-consumer garments containing 70% or more polyester, including blends with elastane and other mixed fibres. Items with trims attached and mixed-colour feedstocks can also be processed. Meltem Kimya converts these materials into GRS-certified rTEX chips, which KIPAS Textiles then uses to produce filament yarns and staple fibres for commercial manufacturing.

The process removes accessories during recycling, reducing labour and manual sorting. Blended fabrics are decolourised to generate cleaner outputs. At the core is Meltem Kimya’s patented molecular recycling technology, which breaks polyester into its base components and rebuilds it without generating microplastics, enabling repeated recycling with no significant loss of quality.

Early assessments suggest this system can cut emissions by nearly 74% compared with virgin polyester production. KIPAS Textiles CEO Halit Gümüser said the platform provides a commercially viable way to transform complex post-consumer waste into high-quality materials at scale.

The development of fibR-e stems from a multi-year collaboration between KIPAS and partner companies, with Meltem Kimya supplying the key molecular recycling expertise. KIPAS will integrate the recycled materials into its own supply chain, supporting large-volume production at competitive pricing.

According to the company, the outputs are traceable, performance-tested, and designed to help brands reduce reliance on virgin resources while meeting tightening regulatory demands.

The launch of fibR-e signals an industrial-scale shift toward closing the loop on polyester waste.