Launch of a record-small 0.65mm orifice at GTTES 2025

Switzerland’s Wattwil, December 26, 2024 At GTTES in Mumbai, India, Heberlein Technology, a pioneer in air interlacing and texturing jets, will present its most recent offerings. The DTY jet insert and the new housing generation HemaJet-LB06 are two important features. APe043, which offers exceptional performance in yarns with exceptionally low denier thanks to its record-small 0.65 mm aperture.

Demand for premium, lightweight textiles made from ultra-fine yarns is driven by the Indian market, particularly for luxury clothing and sportswear. The rise in the production of synthetic fibres makes Heberlein’s ideas crucial for addressing these demands. Guests at Heberlein provides GTTES 2025 with first-han knowledge, and the Swiss firm is cordially welcomed to visit booth D17 in hall 3.

Productivity and profitability are increased with the APe043 Jet Insert.

For ultra-fine yarns down to 20 denier, the APe043 Jet insert ensures smooth production by minimising yarn displacement and avoiding developing knots. This latest technological Development promotes the quick expansion of polyamide filament manufacturing capacity and is in line with the growing demand for premium textiles in international markets. Additionally, the APe043 jet insert has energy-efficient technology that boosts the mill’s earnings.

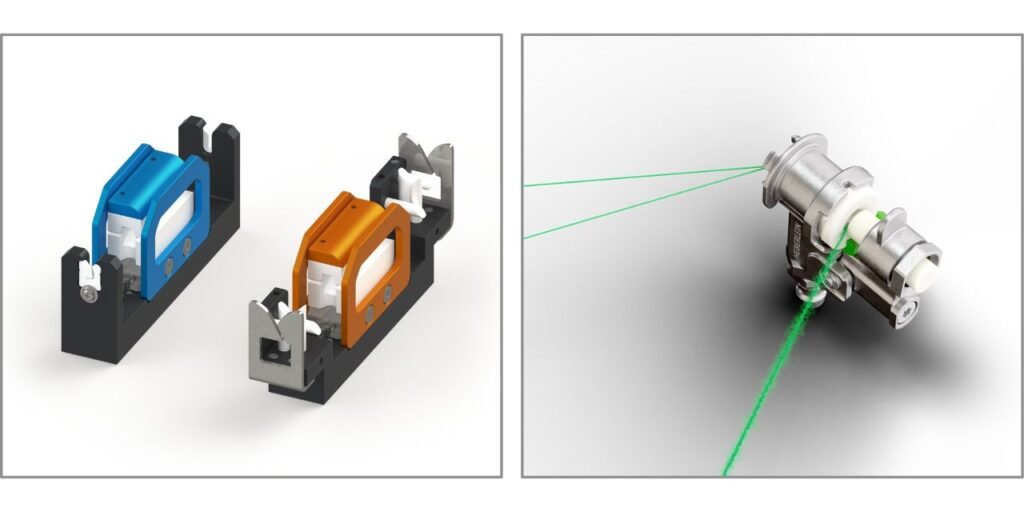

The cost-effective solution for ATY

Heberlein, who is renowned for producing premium jets for air texturing, provides the entire solution from a single source with the HemaJet-LB06. Compatible with the new sturdy HemaJet-LB06 jet housing with the T, A, and S Heberlein jet core series. Because of its adaptability, it is the perfect answer to a variety of air texturing process needs. Using a variety of gauges, it is simple to modify the distance between the impact body and the jet core, enabling exact control and texturing process optimisation.

For many years, Heberlein jet cores have been the dependable choice for the ATY sector. meeting a variety of needs, such as softer, textile yarns made possible by a larger overfeed potential or compact, homogeneous yarns ranging from 30dtex to 3,000dtex. To put it briefly, Heberlein offers the best option for each use case. Customers may select from a fantastic selection of jet cores, and any jet core that meets their demands will also suit the housing, no matter what.

The PolyJet-SP3, a new type of spinning jet, is widely recognised for its ability to spin textile yarn. Manufacturers of technical yarns with high demands greatly value the PolyJet-TG-3-HP405A/WO70 (TopAir). Producing yarn with an unparalleled level of even and consistent interlacing density. Furthermore, this jet impresses customers with strong, reliable knots for high-tenacity yarns (HT and HMLS). Heberlein’s PolyJet-TG-3 achieves more than 12 knots per meter with 1100f98dtex and 1670f98dtex. Additionally, yarn parameters of tensile strength, elongation, and elasticity show smaller variations, for ultimate quality benefits, as well as improved unwinding behaviour of the bobbins.

The SP-3 and TG-3 PolyJet series are typical Heberlein benefits. With a single 180-degree rotation, the high-performance air interlacing jets for technical and textile yarns provide a special quick-release mechanism that allows jet packs to be switched out in a matter of seconds. They also include a roll bar to shield the ceramic surfaces and a small, space-saving design.