By adjusting chemical fertilisers for gradual release and reducing their contact with the rhizosphere soil, water, and microorganisms, a mechanically stable, biodegradable, and hydrophobic nanocoating material can improve the nutrient usage efficiency of chemical fertilisers. By lowering the prescribed fertiliser dosage, this covering composed of nanoclay-reinforced binary carbohydrates can preserve improved crop yields.

As part of the green revolution, chemical fertiliser input procedures have been utilised often over the past 50 years to maintain soil nutrients so that increased plant output may be attained. The frequent and excessive application, pose risk on global sustainable development. Researchers are constantly on the lookout for ways to use fertilisers more efficiently.

Using anionic clay as a reinforcing agent that promotes stable coordination bonds, scientists from the Institute of Nano Science and Technology (INST), Mohali, an independent institution of the Department of Science and Technology, coated muriate of potash (KCl), which provides 80% of the needs for potassium fertiliser, with binary carbohydrates, specifically chitosan and lignin.

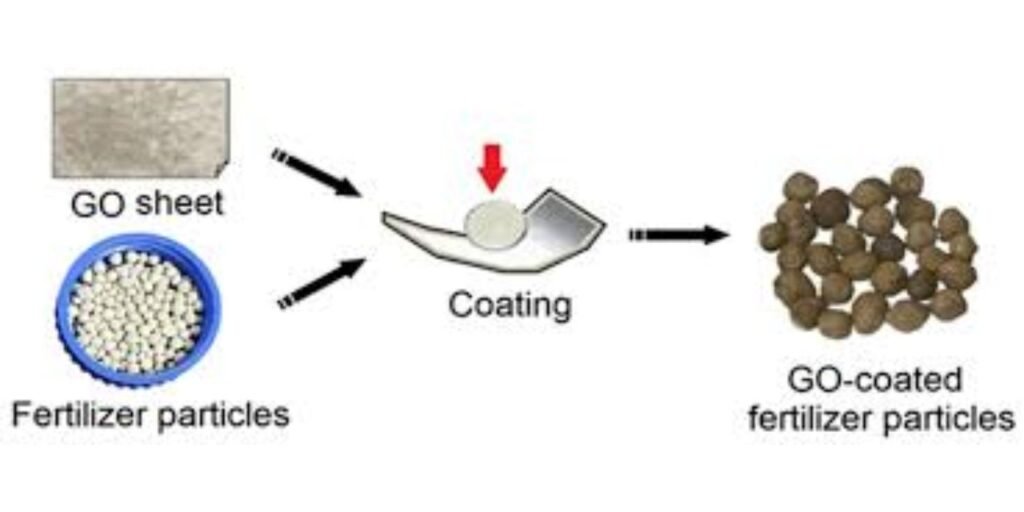

B. K. Sahu, K. Swami, N. Kapoor, A. Agrawal, S. Kataria, P. Sharma, P. Kundu, H. Thangavel, A. Vattakkuniyil, O. P. Chaurasia and V. Shanmugam used drum rotor method to coat the fertilizer in a uniform manner and improve the use efficiency. Low-cost, naturally occurring nanomaterials such as starch, chitosan, and nano-clay were utilised to create the homogeneous covering. Environmental Science: Nano is the publication where the study was published.

adjusting the nano coating material’s hydrophobicity and altering the chemical fertilisers’ release kinetics to suit crop needs. Furthermore, the new product’s life cycle evaluation and biodegradability guaranteed sustainability in comparison to traditional chemical fertilisers. Additionally, the coated fertilizer’s mechanical performance ensures its industrial use throughout the supply chain and transportation.

The biocompatibility and biodegradability of nature-inspired polymers’ 3D nanostructure provide a promising foundation for a range of applications. Hydrophobic nanomaterials were built for the gradual release of chemical fertilisers by taking use of the irreversible denaturation, self-assembled amyloid fibril production, and thermoresponsiveness of natural waste polymers. Additionally, the uniform coating of chemical fertilisers with superior mechanical performance was made possible by the specially designed rotating drum system with sand air cannon.

To improve the efficiency of nutrient utilisation, slow-release fertiliser may be a viable substitute for ordinary fertiliser. More output from less intake is made possible by the lower suggested dosage combined with higher wheat and rice yields. In comparison to traditional fertiliser applications, the country’s economy and the socioeconomic status of farmers will both generally increase.