Noise pollution is a growing challenge in everyday environments such as restaurants, open-plan offices, and schools, often leading to stress and health issues. To address this, sound-absorbing materials are widely used. The German Institutes of Textile and Fiber Research Denkendorf (DITF) are developing an advanced system to measure and predict the acoustic properties of a variety of textiles. This research will enable the design of innovative sound-absorbing and acoustically effective materials.

Currently, foams and nonwovens are commonly used as sound absorbers. While effective, they are relatively thick and lack flexibility. In contrast, woven and knitted textiles are elastic and adaptable, capable of targeting specific frequency ranges and tailoring solutions to distinct noise problems. However, these fabrics have been underutilized in acoustics due to limitations in existing measurement methods.

Nonwovens, with their random fiber arrangement, differ significantly from woven and knitted textiles, which follow recurring patterns. This difference makes existing acoustic testing and simulation models unsuitable for broader textile applications. As a result, manufacturers of acoustic textiles are constrained by limited testing tools.

The MetAkusTex research project aims to close this gap. Dr. Elena Shabalina, Head of the Technology Center E-Textiles & Acoustics at DITF, stated: “In acoustics research, there is limited knowledge about the potential and diversity of textiles. As a textile research institute, we want to ensure that a wide range of textile structures, including 3D textiles, find their way into the world of acoustics. We are laying the necessary foundations for this.”

Through new measurement and prediction methods, DITF is creating mathematical models that evaluate how textiles absorb, reflect, or scatter sound. These methods will allow materials to be tested, customized, and optimized for acoustic performance as early as the design stage, helping companies improve efficiency, sustainability, and speed to market.

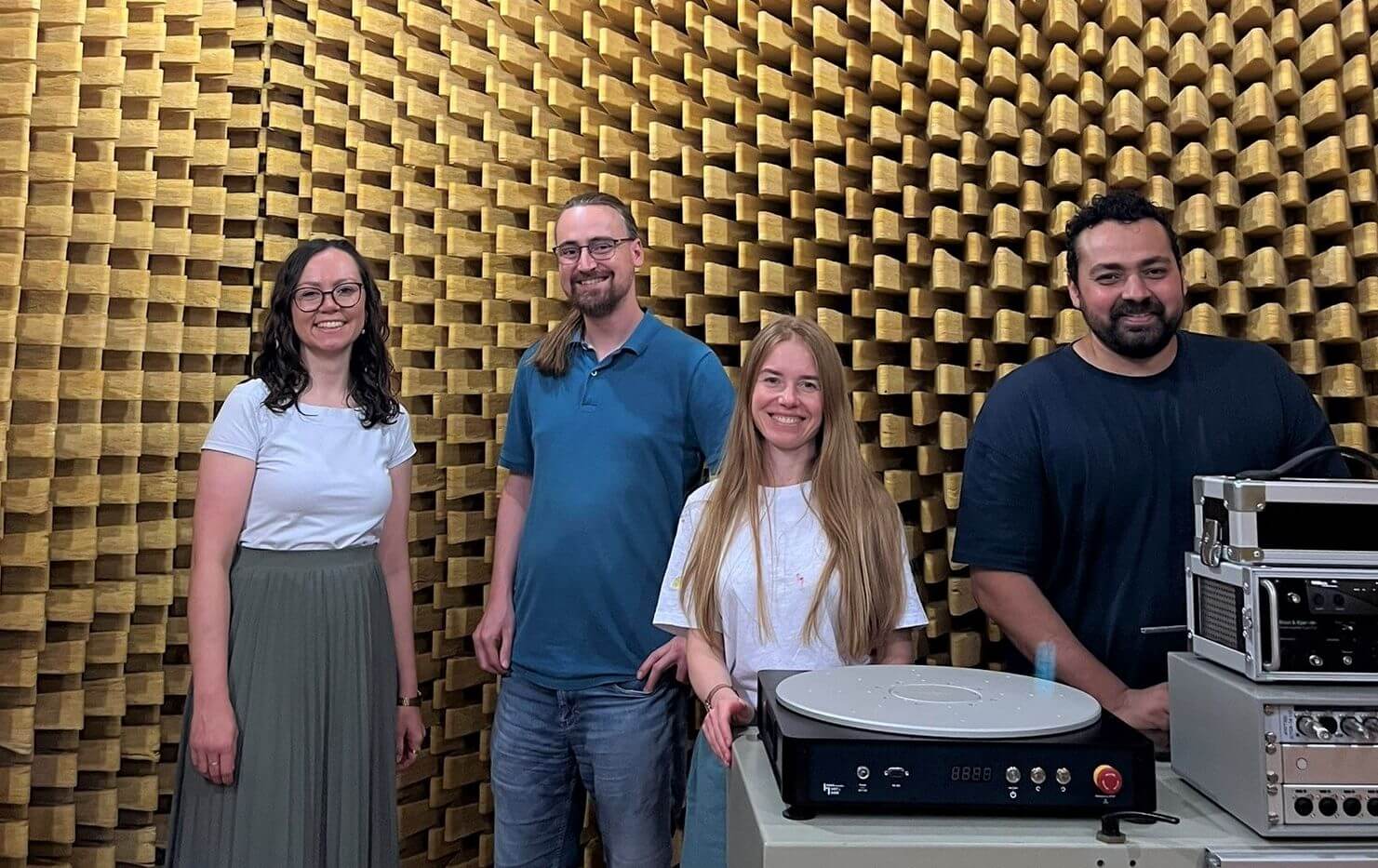

Alongside this, the DITF acoustics laboratory is being upgraded with a semi-anechoic chamber, advanced microphones, loudspeakers, a turntable for speaker quality assessment, and modern data acquisition software. The facility will serve both research and industry testing.

The MetAkusTex project is funded by the Baden-Württemberg Ministry of Economic Affairs, Labor, and Tourism under the Invest BW – Praxissprints program.