How drives, motors, and PLCs are transforming textile production processes. By Umit Kahraman, Global Machinery Segment Manager at ABB.

The textile industry faces a diverse range of challenges, including rising energy costs, complex production processes, evolving consumer trends, and a growing emphasis on sustainability.

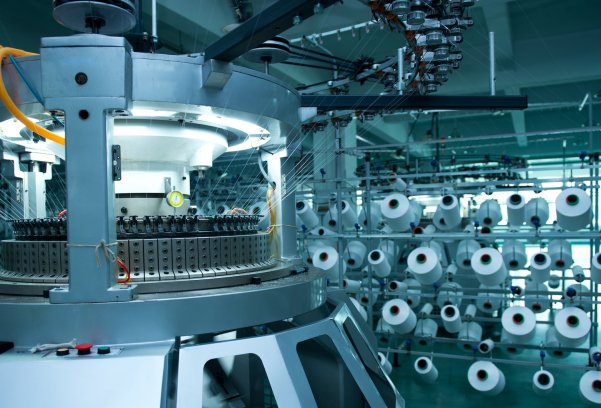

In response, the industry is embracing digital technologies like automation and the Internet of Things (IoT) to transform its operations. These technologies are being utilised to optimise production processes, enhance supply chain management, offer customised products, and enable real-time monitoring and control.

However, despite the potential for growth in this area, only around one-third of textile facilities have integrated automation into their production cycles. This highlights the significant opportunity for growth and the importance of streamlining and optimising textile machines.

As sustainable fabrics and practices gain more popularity and companies prioritise reducing their carbon footprint, the need to enhance energy efficiency while increasing production velocity will become even more urgent. This can be achieved through integrating high-efficiency motors, variable speed drives (VSDs), and programmable logic controllers (PLCs) in textile machines.

Using high-efficiency motors and drives to optimise energy consumption

In recent years, we’ve seen a growing industry-wide commitment to sustainability throughout the production process, including adopting renewable materials and improving energy efficiency. Textile companies are setting specific sustainability targets, responding to increasing customer demands for transparency in smart and sustainable practices.

As a result of the focus on process optimisation, there has been greater investment in high-efficiency motors, such as IE4 or IE5 synchronous reluctance (SynRM) models. These modern motors have already shown they can play a pivotal role in helping to minimise energy usage.

Variable speed drives, also known as variable frequency drives or, simply, drives, are also central to this energy optimisation process. They allow for adjustments in motor speed and torque, giving operators precise control over specific textile applications.

The conscious bid for high-efficiency equipment is being further reinforced by regulatory obligations, such as the Ecodesign Directive, which has provided further impetus to the uptake of these motors and drives.

However, it’s also true that many textile companies are sticking to old processes due to cost concerns. In many cases this is understandable, but it’s based on a somewhat false economy: the higher cost of more efficient technology can often actually be recuperated in a short period, sometimes even a matter of months, purely through energy savings.