As 2025 draws to a close, the Ministry of Textiles stands at the centre of India’s industrial resurgence, steering a wide-ranging agenda that spans infrastructure creation, export growth, sustainability, skilling and farmer welfare. From mega textile parks and technical textile innovation to cotton reforms and global trade expansion, the year has marked a decisive shift towards scale, competitiveness and resilience.

PM MITRA: Mega Parks Move from Vision to Ground Reality

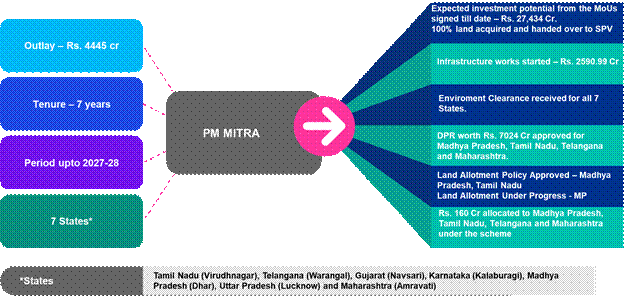

The flagship PM Mega Integrated Textile Region and Apparel (PM MITRA) scheme gathered strong momentum in 2025. Seven parks are being developed across Tamil Nadu (Virudhnagar), Telangana (Warangal), Gujarat (Navsari), Karnataka (Kalaburagi), Madhya Pradesh (Dhar), Uttar Pradesh (Lucknow) and Maharashtra (Amravati), backed by an outlay of ₹4,445 crore over seven years up to 2027–28. Designed with world-class, plug-and-play infrastructure, these greenfield and brownfield projects aim to redefine textile manufacturing at scale.

Investment MoUs exceeding ₹27,434 crore have already been signed, with 100 per cent land acquisition completed and transferred to SPVs. Infrastructure works worth ₹2,590.99 crore are underway across all sites, while environmental clearances have been secured for each park. A major milestone was achieved when the Hon’ble Prime Minister laid the foundation stone for the Dhar park in Madhya Pradesh on 17 September 2025. DPRs worth ₹7,024 crore have been approved for parks in Madhya Pradesh, Tamil Nadu, Telangana and Maharashtra, alongside land allotment policies and fund allocations totalling ₹160 crore.

National Technical Textiles Mission: Innovation at the Core

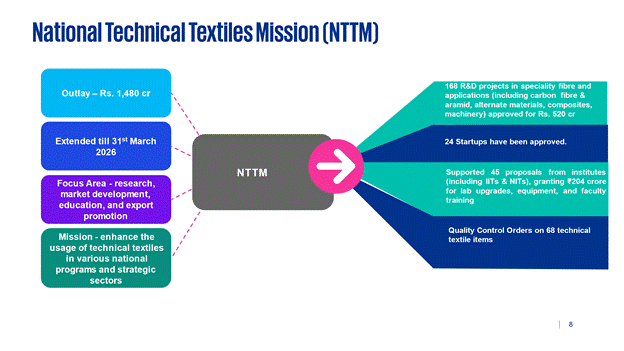

Under the National Technical Textiles Mission (NTTM), extended till 31 March 2026 with an outlay of ₹1,480 crore, India continued to deepen its push into high-performance textiles. During the year, 168 R&D projects covering speciality fibres, carbon and aramid materials, composites, machinery and alternate materials were approved with funding of ₹520 crore. The mission also supported 24 startups and strengthened academia through 45 proposals from institutions including IITs and NITs, backed by ₹204 crore for labs, equipment and faculty training. In parallel, eight Quality Control Orders were notified on 68 technical textile items, reinforcing standards and market credibility.

PLI for Textiles: Investments Translate into Production

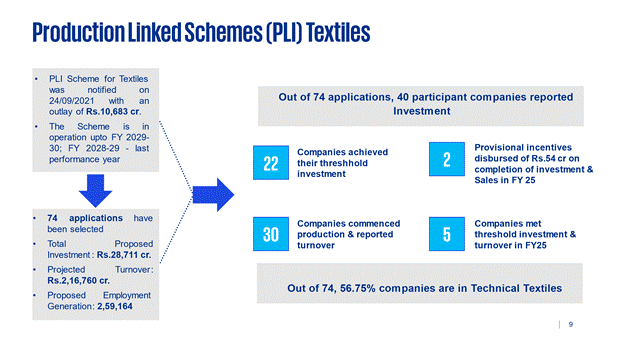

The Production Linked Incentive (PLI) Scheme for Textiles, with an approved outlay of ₹10,683 crore, continued to show tangible results. Out of 74 selected applicants, proposed investments stand at ₹28,711 crore, projected turnover at ₹2.16 lakh crore, and employment generation at over 2.59 lakh. Forty companies reported investments, while 22 achieved threshold levels. Thirty participants commenced production and reported turnover, leading to provisional incentive disbursal of ₹54 crore to two applicants for FY 2024–25. Notably, 56.75 per cent of the selected companies operate in technical textiles, reflecting the capital-intensive nature and strategic focus of this segment.

Textiles Trade Promotion: Exports Power Ahead

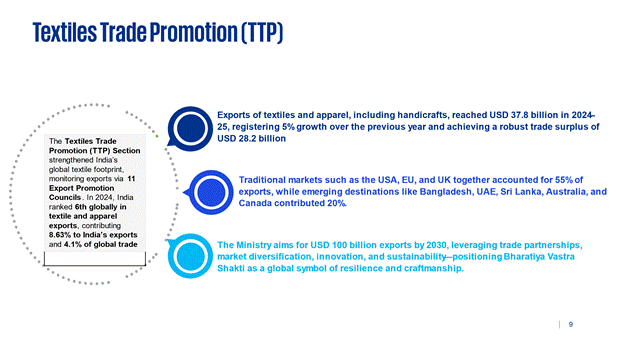

India’s textiles and apparel exports, including handicrafts, reached USD 37.8 billion in 2024–25, registering 5 per cent growth and delivering a trade surplus of USD 28.2 billion. In 2024, India emerged as the world’s sixth-largest exporter, contributing 8.63 per cent to national exports and 4.1 per cent to global trade. Traditional markets such as the USA, EU and UK accounted for 55 per cent of shipments, while emerging destinations including Bangladesh, UAE, Sri Lanka, Australia and Canada contributed 20 per cent. With activity across more than 500 districts in 33 States/UTs, the Ministry has set a Vision 2030 target of USD 100 billion exports, driven by partnerships, diversification, innovation and sustainability under the banner of Bharatiya Vastra Shakti.

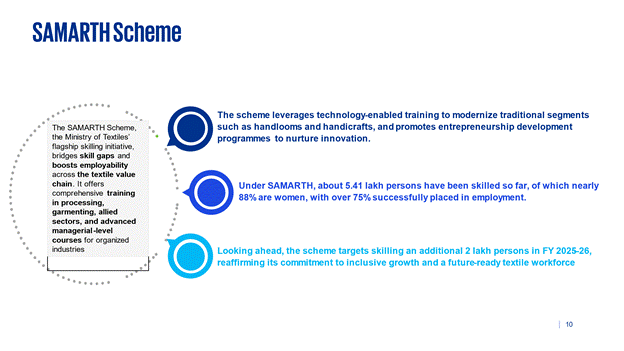

SAMARTH: Building a Future-Ready Workforce

The SAMARTH Scheme continued to reshape textile skilling in India. So far, about 5.41 lakh individuals have been trained, with women accounting for nearly 88 per cent. Over 4.05 lakh beneficiaries have secured employment, reflecting a placement rate of 75 per cent. By modernising handlooms and handicrafts through technology-enabled training and entrepreneurship programmes, the scheme now targets skilling another two lakh persons in FY 2025–26.

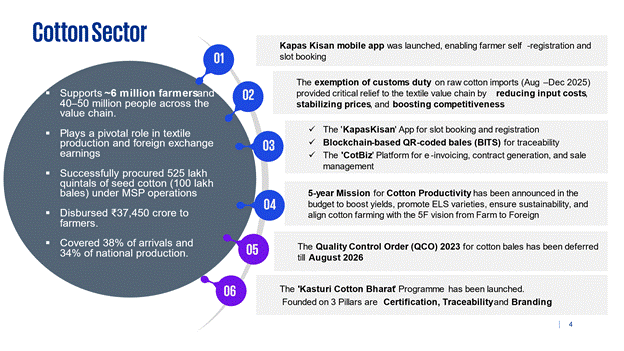

Cotton Sector: Farmer Welfare and Digital Reforms

A backbone of India’s agrarian economy, the cotton sector supported nearly six million farmers in 2025. During the 2024–25 season, the Cotton Corporation of India procured 525 lakh quintals of seed cotton under MSP operations, disbursing ₹37,450 crore and covering 38 per cent of arrivals and 34 per cent of national output. The launch of the Kapas Kisan app enabled self-registration and slot booking, while blockchain-based QR-coded bales under BITS enhanced traceability. The CotBiz platform streamlined e-invoicing and sale management.

Customs duty exemption on raw cotton imports from August to December 2025 provided vital relief to the value chain. A five-year Mission for Cotton Productivity was announced to boost yields and sustainability, aligned with the 5F vision from Farm to Foreign. The Quality Control Order for cotton bales was deferred till August 2026, and the Kasturi Cotton Bharat programme was launched to strengthen certification, traceability and branding of Indian cotton.

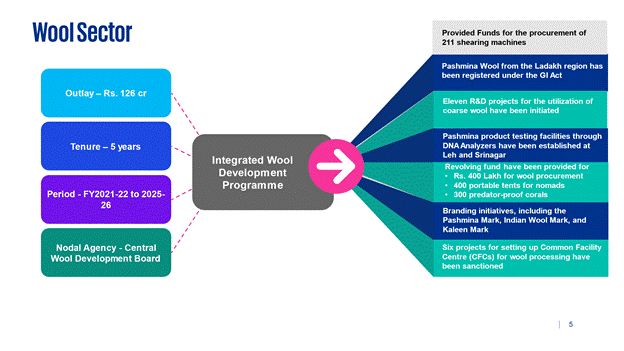

Wool, Silk and Jute: Strengthening Natural Fibre Ecosystems

Under the Integrated Wool Development Programme with ₹126 crore allocation, initiatives ranged from GI registration for Ladakh Pashmina to R&D on coarse wool, DNA testing facilities, shearing machines, revolving funds and branding marks such as Pashmina Mark and Indian Wool Mark.

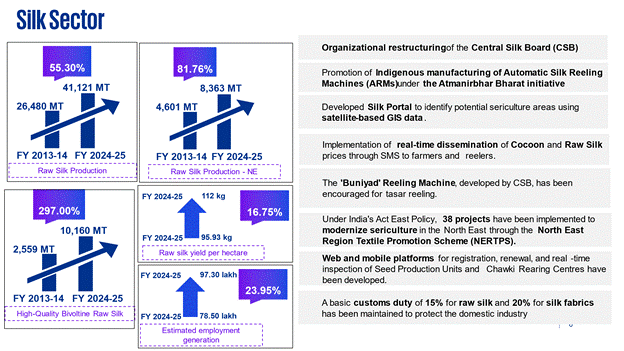

In silk, raw silk production rose to 41,121 MT in 2024–25, marking a 55.30 per cent increase over 2013–14, while bivoltine silk surged nearly fourfold to 10,160 MT. Employment touched 97.30 lakh persons. Key reforms included restructuring of the Central Silk Board, indigenous ARM machines, the SILKS GIS portal, SMS-based price dissemination and the Buniyad reeling machine for tasar silk. A basic customs duty of 15 per cent on raw silk and 20 per cent on silk fabrics was maintained.

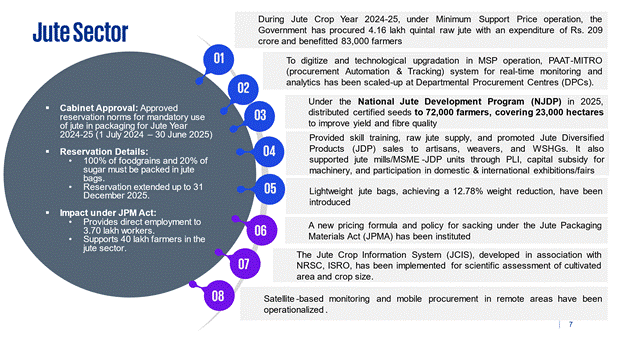

The jute sector saw extension of mandatory packaging norms till December 2025, benefiting 3.70 lakh workers and 40 lakh farmers. MSP procurement reached 4.16 lakh quintals at ₹209 crore. Digitisation through PAAT-MITRO, lightweight jute bags, JCIS satellite monitoring and support under NJDP reinforced both sustainability and livelihoods.

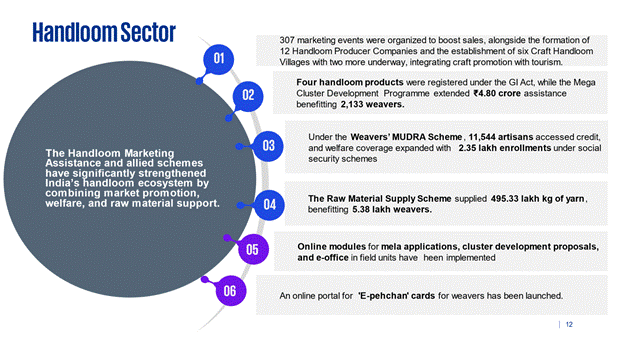

Handloom and Handicrafts: Craft Meets Commerce

Marketing events, GI registrations, mega clusters and Mudra credit expanded opportunities for weavers, while yarn supply of 495.33 lakh kg supported over 5.38 lakh artisans. In handicrafts, over 1.30 lakh artisans were registered under Pehchan, with producer companies, marketing events, design, skill training and R&D programmes benefitting tens of thousands. The launch of IndiaHandmade.com and Bharatiya Vastra Evam Shilpa Kosh portals further boosted digital reach.

NIFT: Fashion Education Goes Global

The National Institute of Fashion Technology marked 2025 with its 19th campus at Varanasi, a new UG programme and the Begusarai Extension Centre. International showcases in London, release of VisioNxt Trend Book and INDIAsize charts, collaborations with TRIFED, and the launch of the NIFT Fashion Journal highlighted its growing academic and industry leadership.

Policy Reforms: Enabling Exports and Ease of Doing Business

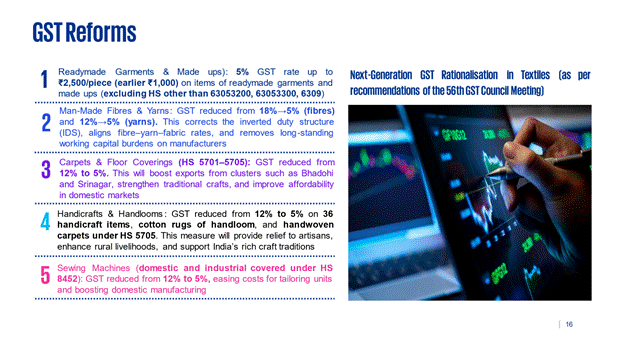

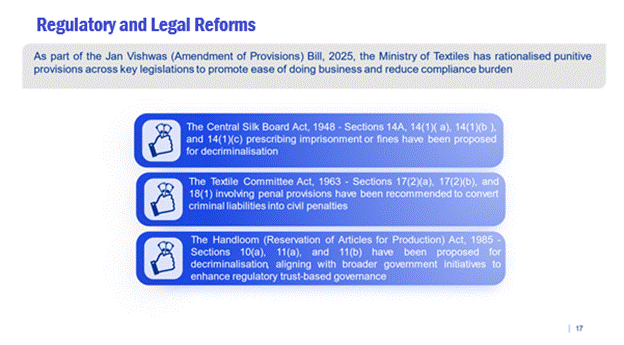

Major reforms included GST rationalisation—cutting rates on MMF fibres and yarns to 5 per cent, garments up to ₹2,500 to 5 per cent, carpets, handicrafts and sewing machines to 5 per cent—correcting inverted duty structures and easing costs. Under Jan Vishwas reforms, penal provisions across textile legislations were proposed for decriminalisation.

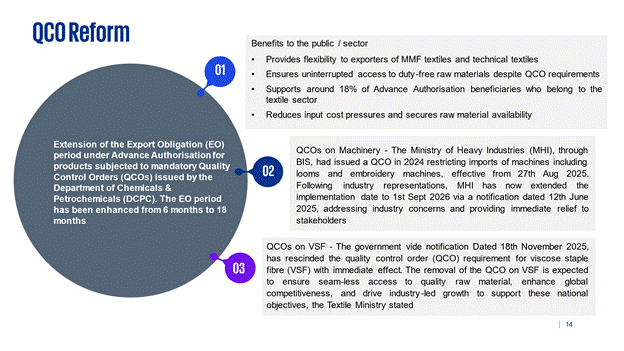

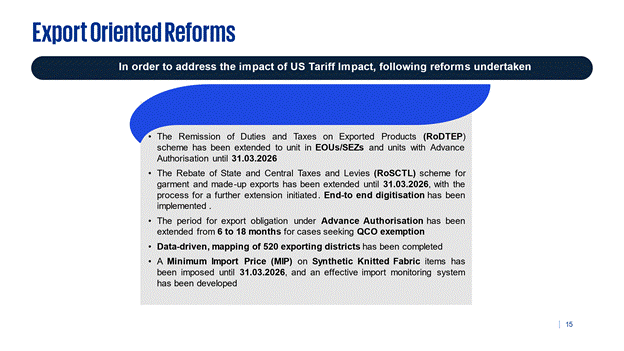

Export-oriented measures extended RoDTEP and RoSCTL till March 2026, expanded EO periods to 18 months for QCO exemptions, mapped 520 exporting districts and imposed MIP on synthetic knitted fabrics.

On QCO reforms, the government extended machinery QCO implementation to September 2026 and rescinded the QCO on viscose staple fibre. “The removal of the QCO on VSF is expected to ensure seam-less access to quality raw material, enhance global competitiveness, and drive industry-led growth to support these national objectives,” the Textile Ministry stated.

Bharat Tex 2025: India’s Textile Power on Global Display

Held from February 14 to 17, 2025, at Bharat Mandapam, New Delhi, Bharat Tex 2025 emerged as India’s largest textile event, spanning 2.2 million sq ft with over 5,000 exhibitors and 1,20,000 trade visitors from 120+ countries. Showcasing more than 12,000 products and hosting 70+ knowledge sessions, the event advanced the Farm to Fibre, Fabric, Fashion and Foreign Markets vision, as India targets tripling exports to ₹9 lakh crore by 2030.

Together, these initiatives reflect a year where policy, investment and innovation converged—positioning India’s textile sector as a global powerhouse built on scale, sustainability and skilled human capital.