R.R.Joshi1

Shubham M. Agrawal2, Tejas S. Dadmode2, Om M Pandhare2,

2Student, 1Lecturer

Department of Textile Engineering, DKTE Soctiety’s Textile & Engineering Institute ,Rajwada, Ichalkaranji, Maharashtra, India

*Corresponding Author: joshi.design@gmail.com

ABSTRACT

Rapid prototyping technologies are able to produce physical model in layer by layer manner directly from their CAD without any tool, Dies and Fixture. Compared to traditional process the rapid prototyping is capable to manufacture complex parts easily and quickly. RP helps in earlier detection and reduction of design error. In present study parameters such as percentage infill material, Layer Thickness, orientation of specimen was varied. Infill pattern was kept Honeycomb because this structure has obtained best results as compared to other structures. Orientation parameters were varied in 00, 450, 900 with respect to horizontal plane. Using Taguchi’ Design of experimental procedure for L9 orthogonal array of three parameter with 3 different levels from 27 experiments a total of 9 experiments were selected for testing. Best tensile strength as obtained for specimen with ABS material of 0.1mm layer thickness, 60% infill, orientation perpendicular.

INTRODUCTION

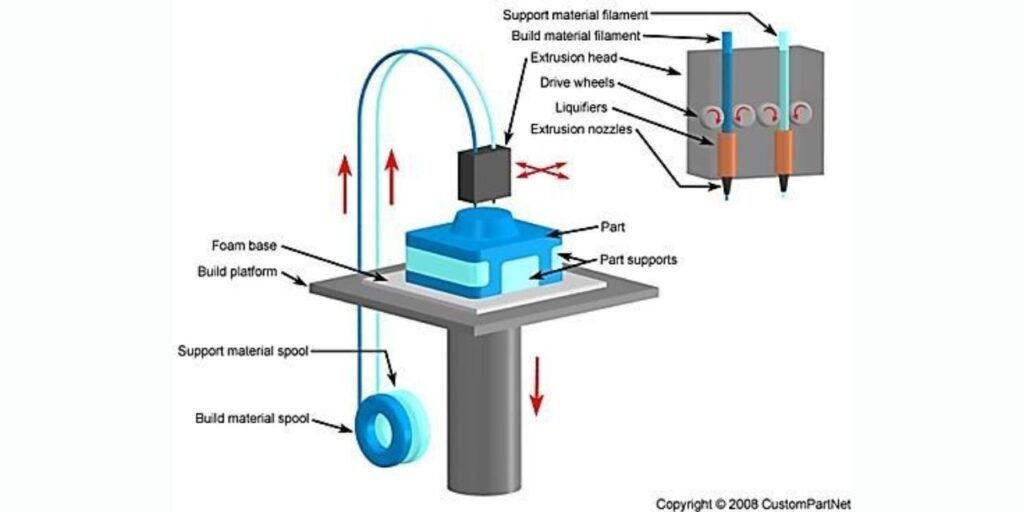

Fused deposition modelling is the most used manufacturing process among all the processes of the rapid prototyping as it has wielded rang of the applications and ease of availability of the required facility respect to the FDM process. The study of variation in the manufacturing process like layer thickness, infill percentage and orientation lead to driver the best out of the combination respect to all the considerable characteristic’s and parameter. we have to design the specimen as according to the tensile test format so we are selected the ASTM D638 standard.

Now the part of manufacturing the specimen using the Fused deposition modelling. First step of the manufacturing the specimen is creating the Cad file using the various software of 3D modelling like fusion 360 solid works and many more 3D modelling software. Then file of model is converted to the file format of STL file format. Then next slicing of the specimen is created using the STL file using the Cura, fusion 360 and many more slicing software, where model is converted to the number of layers as required in the FDM process. Then this file is given to the rapid prototyping FDM machine for the manufacturing of the specimen. At the end after deposing various layer we get the 3D printed job as according the required dimensions.

LITERATURE REVIEW

K.N Gunasekaran, et.al [1] mentioned Using the PLA wire filament of density 1.24 g/cm^3 the specimens under optimum printing condition were printed through FDM process with varying the infill percentage. The mechanical properties of PLA printed specimens increased with the increase in the infill percentage form lower value to the higher one. The PLA specimen printed with infill density of 100% shows the value of hardness, tensile strength, impact strength and flexural strength as 97 HRC, 53Mpa, 70j/m^2 and 53MPa. Hence PLA specimens printed with higher infill percentage can be used for building components of various applications like Automobiles, toys, decorative materials etc

K. Durgashyam, et.al [2] written in their journal that for showing the tensile properties of the PETG material layer thickness, feed rate of the material will be minimum with higher percentile of infill density. On the other hand, at minimum layer thickness, at moderate feed rate and at lesser percentile of infill density, the material exhibits good flexural property. The contribution of layer thickness for tensile strength was 57.82% and for flexural strength it was 41.87% respectively. Sunil Khabia, K.K. Jain [3] elaborate that For the ABS material the which is tested under the tensile stress got the values of 25.58MPa to 37.50MPa as varying the percentage of the material in the specimen. PLA is stronger than the ABS as it has less elongation due to less plasticity properties.

Bitthal Saraf, et.al [4] written in their journal that Adhesive materials are used to joint two specimens. The adhesive material which is used in the test is dimethyl ketone (acetone). And results show more strength during tensile test in the two specimen which are joined with help of the adhesive as compared to the single specimen. Also, in the variation of orientation angle between 900 and 450, the 450 have great strength as it has closed packed structure. V. harshitha, [5] elaborated that Ansys is the software used for the analysis of the various static and dynamic test of the different component by virtual method. The manufacturing the specimen by fused deposition modelling method and using the digital 3D file which is created using different modelling software like Solidworks, Cura, fusion 360 and many more.

Cristina Văleana, Liviu Marșavinaa, et.al [6] they have shown that ne of the most studied technologies for obtaining different parts is Additive Manufacturing. Whether it is about plastic or metal materials, AM is used because very complex parts can be obtained, without further technological operations. From all AM technologies, Fused Deposition Modeling is the most used all over the world, due to its cost-effective way of printing. FDM is based on the extrusion of a wire, through which a piece is formed by successively depositing layer-by-layer of molten material. This paper experimentally investigates the tensile properties of 3D printed specimens obtained through FDM printing. The influence of spatial printing direction and size effect on main mechanical properties was investigated. Polylactic acid dog bone specimens were adopted for all tensile tests.

V. harshitha, et.al [7] described in their study that Ansys is the software used for the analysis of the various static and dynamic test of the different component by virtual method. The manufacturing the specimen by fused deposition modelling method and using the digital 3D file which is created using different modelling software like Solidworks, Cura, fusion 360 and many more. Then the file is converted to the. step or .stp file which is further required in the analysis software like Ansys. Using the Ansys workbench we can calculate required values of the tensile test.

Dong-Woog Haa, et.al [8] shown that the tensile strength of DP590 was 632 MPa, and it exhibited typical steel sheet characteristics that did not break after reaching the maximum strength, and the necking phenomenon occurred because of the decrease in cross-sectional area. In the case of A356, the tensile strength of the as-received material without heat treatment was 240 MPa, which was approximately 2.5 times lower than that of the DP590. Andrzej Szewczak, et.al [9] mentioned that Epoxy adhesive is the industrial adhesive material which can be used for quick joining of the two parts having mechanical properties of 2100 MPA elastic modulus at the mass density of 1.2g/cm^3 and tensile strength of 40Mpa.

Daniel Farbman, et.al [10] shown in their studies that As here various infill percentage are used for the testing of mechanical properties and solution is the as we have maximum infill percentage we get maximum strength of the material and after studying various Manufacturing Pattern for printing we have selected Honeycomb structure as it have maximum load caring capacity Vishal Wankhede et.al [11] published that Rapid Manufacturing is an Additive Layer Manufacturing Process where intricate engineered models are prepared from their Computer A idled Design models by addition of material in a layered fashion. With Increasing key emerging technologies rapid manufacturing has gained much focus in the modern era. Additive manufacturing process named Fused Deposition Modeling has remarkable applications in several industries.

Dinesh Yadava, et,al [12] shown there work that The present work deals with the effects of significant parameters of the Fused Deposition Modeling 3D printer on the tensile strength of materials like PETG , ABS and multi-material The significant process parameters have been taken as ex torsion temperature, layer height and material density ASTM D638 standard test specimens have been prepared at different process parameters of the FDM 3D printer to check their tensile strength. T.H Bhatia Singh, et.al [13] published that Additive manufacturing is one of the most useful technologies that have been studied by many researchers in terms of the ability to create complex geometries, eliminating wastages, reducing human interventions etc. Fused Deposition Modeling (FDM) is one of the most commonly used manufacturing technologies due to easy fabrication process, flex ability of materials, accuracy and portability.

Rahul Koneru et.al [14] described on their work that in this paper, comparisons of the adhesive strengths of two commercially available adhesives epoxy and cyanoacrylate late, on 3D printed plastic materials, Acrylonitrile Sty reneAcry late and Nylon 12 Carbon Fiber were carried out. The single lap shear test is used to determine the adhesive properties of the specimens with and without post-curing at elevated temperature. A comparison is made with fully printed, non-bonded specimens to give a relative gauge of the performance of the adhesives. Harsh Vardhan, et.al [15] said that FDM is used by many industries for prototyping and end-use components due to lower cost and its versatility of material usage. Researchers have used variety of reinforcements for enhancement of mechanical properties of feedstock filament used for FDM.

Aleksa Milovanovic et.al [16] have performed experiment on the various parameter affecting the factor of strength, surface roughness and quality of the printed specimen. Fused deposition modelling is the process used in this testing method. Various parameter get changes and test is performed to get output that what is the difference in the strength of PLA material of the filament. Additive manufacturing (AM) is being established as a fabrication technology that brings revenue to the aerospace industry throughout its supply chain and repair operations joel.c. Najmon et.al [17] have studied various additive manufacturing process including various rapid prototyping process and from all of the process its clear that Fused deposition modelling is the most favourable process among all of the processes as 70% of industries uses fused deposition modelling process.

Masayoshi Arizawa et.al [18] have studied on the slicing software which is used during the manufacturing process of the 3D printing specially fused deposition modelling. As for the fused deposition modelling, we need number of layers as the process is carried out in the manufacturing by the number of layers so that 3D object created in the software is converted into number of the layers. This process is known as preprocess of the rapid prototyping by fused deposition modelling.

Tensile Testing

Tensile testing of our job is done by using Polymer Universal Tensile testing. This Polymer UTM is manufactured by FIE Group and its model name is UNITEC 9450 which is fully automatic machine. Having load range of 0-50KN. Machine has crosshead speed range if 0.5-500 mm/min. clearance between upper and lower column is 450mm. This machine works on the 230V and 50Hz frequency. We used to calm our job inside the specimen and applied 1mm/min of tear rate. All inputs are given by using computer like dimensions of the rate of tear. All results are generated inside the software are taken in softcopy and converted in form of PDF.

Figure 3: Tensile Testing Setup.

Tensile Testing

Tensile testing of our job is done by using Polymer Universal Tensile testing. This Polymer UTM is manufactured by FIE Group and its model name is UNITEC 9450 which is fully automatic machine. Having load range of 0-50KN. Machine have crosshead speed range if 0.5-500 mm/min. clearance between upper and lower column is 450mm. This machine works on the 230V and 50Hz frequency. We used to calm our job inside the specimen and applied 1mm/min of tear rate. All inputs are given by using computer like dimensions of the rate of tear. All results are generated inside the software are taken in softcopy and converted in form of PDF.

Result generated through the software contains various information like tensile test, elongation, applied load and maximum displacement. The graph of the displacement vs load is also generated inside that software

RESULTS

After conducting the test on the specimen of PLA-PLA we got the results of various parameter and one graph in the form of Load vs Displacement in which we got the maximum load of 76.631kgf with the maximum stress of the 34.54 MPa, and displacement of 2.26mm for particular specimen similarly we got the results for ABS-ABS as maximum load of 61.270kgf with the maximum stress of the 30.349 MPa and displacement of 2.29mm for ABS material. Now for the combination of the two specimen as we have expected that we will get the results in between this two specimen we got maximum load of 72.712 Kgf with maximum stress of the 32.166 MPa and displacement of the specimen is 2.37mm.