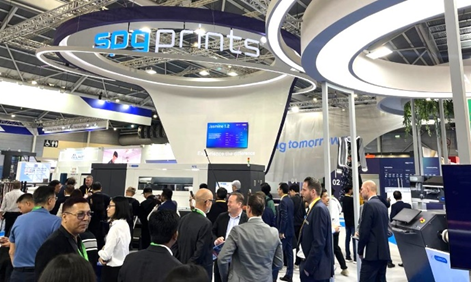

SPGPrints, the global leader in innovative textile printing solutions, today announced an overwhelmingly successful participation in ITMA ASIA 2025 at the Singapore Expo. The event not only showcased the company’s commitment to sustainable and high-efficiency technology but also resulted in the finalisation of several major orders with key industry players and the expansion of strategic market representation.

Revolutionising the Textile Landscape

The SPGPrints booth was a hub of activity, drawing significant interest in its new generation of printing and engraving systems designed to tackle the industry’s most pressing challenges of efficiency and environmental impact.

The highlighted innovations included:

Jasmine (Digital Printing Machine): This new high-speed, 64 Printhead direct-to-fabric digital printer captivated visitors with its ability to produce vibrant designs with minimal water and energy consumption, promising a paradigm shift in customised textile production.

TEAK (Rotary Screen Printing Machine): The TEAK fully automatic machine sets a new standard for conventional printing, featuring advanced automation, accuracy in printing and efficiency for unmatched productivity and print quality.

LARCH (Direct Laser Engraving Machine): The LARCH demonstrated SPGPrints leadership in imaging technology, offering a waterless, rapid engraving process that significantly streamlines the screen preparation workflow.

Sustainable Coated Screens: A major highlight was the introduction of coated screens specifically engineered to dramatically reduce nickel discharge during pigment and discharge printing, reinforcing SPGPrints dedication to sustainable manufacturing practices.

Strategic Market Triumphs and Key Order Closures: The tremendous response translated directly into significant commercial success, with numerous orders concluded on-site. The confidence placed in SPGPrints new technology by leading manufacturers underscores the immediate value these innovations bring to the market.

Confirmed Orders from Leading Subcontinent Manufacturers: SPGPrints is pleased to confirm the closure of substantial orders for its new machinery lines with prominent textile producers across Asia.

Customer Shri Bahubali Traders (India) is committed to investing in the new SPGPrints Direct laser engraver to upgrade their printing capabilities, high-quality, enhance efficiency and meet international sustainability standards. The agreements represent a significant step in modernising their large-scale operations.

One more leading textile printing group, having an entire process setup for conventional flatbed and rotary printing machines, now stepping into the digital printing process, who understand the importance of digital printing and the influence of quality by the machine finalised a major deal with 2 Jasmine machines and one LARCH direct laser engraver.

These orders validate the immediate need for the high-efficiency, sustainable solutions that SPGPrints offers.

Strategic Expansion: Furthermore, strengthening its global reach, SPGPrints officially signed an agency agreement with STD&S to represent its printing portfolio of products in the burgeoning Vietnam market. This partnership marks a significant step for both companies in aligning global technology leadership with local execution excellence. SPGPrints and STD&S are confident that Vietnamese customers will benefit from access to cutting-edge digital printing platforms combined with dedicated, local customer care. The agreement is expected to support accelerated digital-printing adoption in Vietnam and strengthen both firms’ footprint in the region.

“The volume of interest and the number of immediate orders placed at ITMA ASIA 2025 have exceeded our expectations,” said Mr Shailesh Wani, BU-Head (Textile), at SPGPrints.

SPGPrints remains dedicated to driving innovation in the textile industry, providing solutions that not only meet today’s production demands but also set the standard for tomorrow’s sustainable manufacturing.