The global diaper market for infants and the elderly is growing. This has been driven by rising standards of living in populous countries like China and India. Manufacturers are meeting the challenge with innovative technologies.

The baby diaper vertical is expected to reach US$ 70.4 billion by end-2024, up by 4.1 per cent. Growth in the adult-diaper market is outpacing that of every other paper-based household staple, due in part to an ageing population but also due to the elimination of the stigma of using such products. According to Global Market Insights ‘industry analysis report, the disposable incontinence product market size was over US$ 8 billion in 2015 and is expected to exceed US$ 12 billion by 2024.

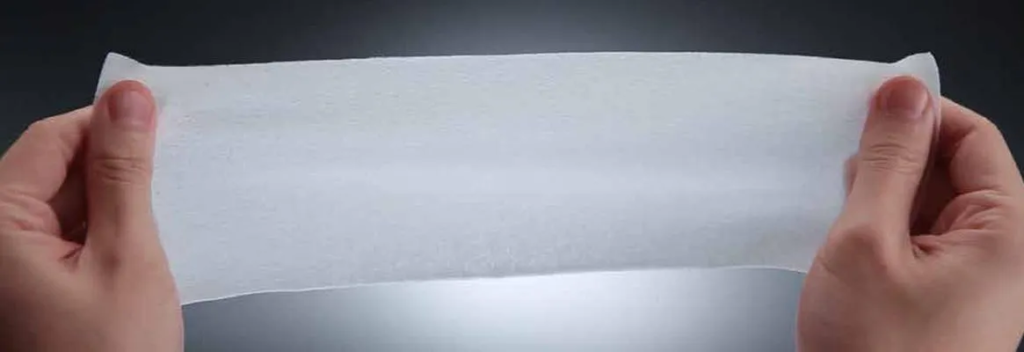

Not only is the need for dispersant incontinence products increasing, consumers are demanding more comfort and performance. Manufacturers are using innovative new technologies, producing disposable diapers and underwear with softer, lighter and smoother fabrics that are constructed to fit well with high elastic functionality. Research and development in the properties of nonwoven fabrics has thrown up choices ranging from crisp to fluffy, abrasive to soothing, and tearable to extremely durable. With so many options in fabrics and the technologies to convert them, manufacturers have a lot to choose from.