Revolutionary Thermoreversible Adhesive Technology for Sustainable Fashion

A Breakthrough in Textile Recycling

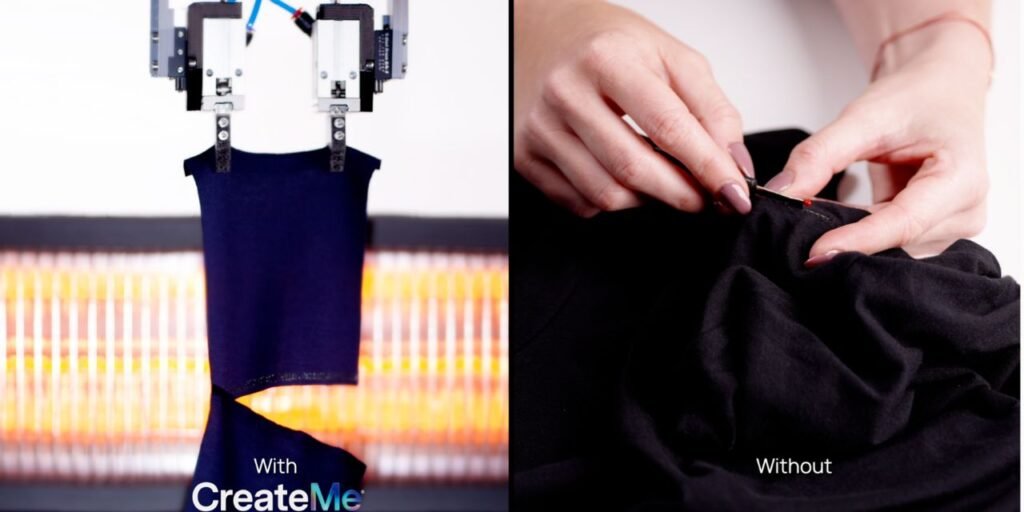

Researchers at The University of Warwick, in collaboration with apparel automation pioneer CreateMe Technologies, have developed an innovative thermoreversible adhesive technology set to transform the fashion industry. This groundbreaking advancement, resulting from three years of intensive research and backed by 19 patents, makes textile recycling more scalable, reducing waste and enhancing sustainability in apparel manufacturing.

Advanced Adhesive Science

The research, led by Professor Remzi Becer and Dr. Dan Mackinnon from Warwick’s Department of Chemistry, alongside Dr. Yixin Liu, Research Scientist at CreateMe, has resulted in an adhesive that allows garments to be bonded at low temperatures and later disassembled at high temperatures (above dry-cleaning levels).

This technology tackles one of the fashion industry’s biggest challenges—textile waste, with an estimated 92 million tons of fabric discarded annually due to inefficient recycling methods.

Expert Insights

Professor Remzi Becer stated: “This collaboration demonstrates how material science and automation can converge to address global sustainability challenges. The potential applications extend beyond fashion, influencing industries such as healthcare, automotive, aerospace, and home goods.”

Transforming the Fashion Industry

The fashion industry currently generates 92 million tons of textile waste annually, much of which ends up in landfills. Traditional textile recycling is labour-intensive and inefficient, requiring manual de-stitching and separation of materials. This thermoreversible adhesive enables fully automated bonded assembly and disassembly, significantly improving the efficiency and scalability of textile recycling.

This innovation ensures that disassembly occurs at higher temperatures than standard washing cycles, reducing premature failure and extending the life of garments until they are ready for recycling.

Industry Impact and Future Applications

Cam Myers, Founder and CEO of CreateMe, emphasized the significance of this development: “CreateMe is uniquely positioned to transform how apparel is made. Our thermoreversible adhesive science paves the way for enhanced recycling opportunities as part of our automated assembly manufacturing process. This technology supports in-market, on-demand apparel production while significantly improving sustainability.”

The timing aligns perfectly with new Extended Producer Responsibility (EPR) legislation in Europe and select U.S. states, introducing stricter requirements for apparel end-of-life management. This game-changing innovation supports the wider adoption of locally produced apparel and facilitates efficient recycling.

Scaling Up for Global Impact

CreateMe and Warwick are actively engaging with industry leaders to scale this groundbreaking adhesive technology, expanding its applications beyond fashion. Through beta testing and licensing opportunities, the technology holds immense potential for industries reliant on efficient, circular production models, including automotive, aerospace, healthcare, and home goods.

This scalable approach marks a significant step forward in sustainable apparel manufacturing and global recycling efforts, paving the way for a more environmentally responsible future.